Author: Tim Scott, Head of Sales, Condair plc

Legionnaires' disease & humidifiers - what you need to know

Humidifiers bring many benefits to production environments, offices and shops, museums and galleries and the home, and are very rarely associated with Legionnaires’ disease. However, poorly designed systems which might be inadequately installed, commissioned or maintained can increase the risk of the disease and, in the UK, particular legislation requires us to be aware of the risk and manage it appropriately.

This article provides information on Legionnaires’ disease and humidifiers, the legislation that governs it and how that risk can be minimised.

Legionnaires’ disease – what is it?

Legionnaires' disease is a type of pneumonia, first identified after an outbreak at a meeting of members of the American Legion in Philadelphia in 1976. The disease is relatively rare but its effects can be serious and even fatal. In the 1976 outbreak, 34 out of 221 people who caught the disease are reported to have died.

Legionnaires’ disease is one of a group of similar diseases collectively known as legionellosis. Others members of this group include Pontiac Fever and Lochgoilhead Fever but Legionnaires’ disease is the most common and the most serious, and is caused by a strain of the bacterium Legionella pneumophila.

Legionella pneumophila exists widely in nature....

Legionella pneumophila exists widely in nature and is found in bodies of water like ponds and lakes, and also in the soil. The disease is spread by people inhaling a contaminated aerosol of fine water droplets, typically containing a much higher concentration of the bacterium than is found in nature, deep into the alveoli of the lungs. Not everyone who inhales an infected aerosol will show symptoms of the disease. It depends on the dose inhaled and their susceptibility.

Some groups of people are more vulnerable to Legionnaires’ disease than others; middle-aged and older people are more susceptible than the young, and men are more likely to contract the disease than women. It more commonly affects smokers and people with respiratory problems and is fatal in approximately 12% of cases. This figure can be significantly higher in hospitalised and immunocompromised people.

Symptoms of Legionnaires’ disease develop within 2 to 10 days of exposure, and include high temperature, coughing, muscle aches, headache, mental confusion, and diarrhoea. Pneumonia can develop and it can result in death. It can be treated successfully with antibiotics but, because the symptoms are similar to ‘flu it’s sometimes not caught early enough.

The Health and Safety Executive (HSE) reports that about half the cases of Legionnaires' disease found in the UK are caught abroad. The other half are the result of infections acquired in the UK. Outbreaks relate to man-made water systems where temperatures are warm (20-45°C) and where the water is fairly static such as in a large water tank or rarely used pipe, both of which favour the growth of Legionella. It is also encouraged by nutrients in the water (which might come from the materials used in the system), limescale and a biological sludge called biofilm.

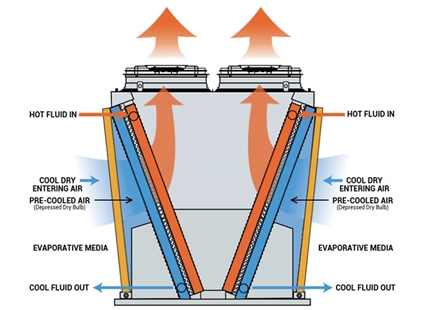

The 1976 case related to spray from a cooling tower, which is still a common source of infection, and evaporative condensers, spa baths, showers, sprinkler systems, fountains and humidifiers are all possible sources, together with many others.

Legal requirements

To prevent outbreaks of Legionnaires' disease, UK companies must comply with regulations published by the HSE that require them to manage and maintain their water systems safely. Under their Approved Code of Practice, ACoP L8, Legionnaires’ disease: the Control of Legionella Bacteria in Water Systems, building owners and occupiers have a legal responsibility to carry out risk assessments on their water systems, prepare and put in place a plan to counter any risk, to monitor its effectiveness and record all activities undertaken and their results. As they form part of the water system in a building, humidifiers must be included in this. Despite widespread publicity and regular conferences, many companies are still unaware of the obligation they have to counter the disease.

If the responsible party does not fulfil their obligations under L8 and an outbreak of Legionnaires’ disease occurs, they could be liable to prosecution. The HSE considers Legionnaires’ disease to be entirely preventable through good design and good practice, and the penalties for failing to act on this are severe. Individuals and organisations can face heavy penalties under the Health and Safety at Work Act for failing to comply. In cases where death is the result, a prosecution for manslaughter might ensue.

However, it isn’t only owners and occupiers that have responsibilities under L8. Designers and suppliers of equipment that forms part of a water system, such as humidifiers, have an obligation to ensure that the design of that equipment is as safe as possible, having carried out a risk assessment and failure mode effect analysis of the product. Instruction manuals should reflect any risk, and provide guidance on correct installation and good practice to keep the risk minimised, such as through appropriate maintenance and cleaning.

Design consultants also have obligations under L8. They should be aware of needs of the plant after installation, and ensure, for example, that it allows ready access for routine cleaning and testing.

Contractors and installers are required to ensure installation in accordance with the manufacturers’ instructions, and should pass on information about good practice and risk to their clients. To be safe, contractors must always ensure the system is installed in line with the manufacturer’s specifications, that it is commissioned competently, that the end-user understands the maintenance requirements and is in possession of the relevant manuals and schedules.

Maintenance companies should work together with the end user or building occupant to ensure that each party understands clearly where their responsibility ends and the other party’s obligations start.

Even though a nominated individual might have responsibility for ensuring that effective monitoring and control systems are in place, everyone in the chain from designer, manufacturer, supplier, installer, maintenance organisation, building occupant or owner, has some element of responsibility for Legionnaires’ disease prevention. Everyone involved should read the manufacturer’s manual and ask questions if unsure.

Risk factors with humidifiers

Compared with other sources of Legionnaires’ disease, such as cooling towers and spa baths, humidifiers represent a relatively low risk but this is no reason for complacency. As devices that introduce aerosols into the atmosphere by design, or that can inadvertently create an aerosol, they must be closely examined in any building’s water system risk assessment.

Humidifiers are often complex appliances that require specialist attention so it is always best to get advice from the manufacturer or supplier (any quality supplier will be happy to give advice on this subject). If not, get a specialist in water systems to advise. Things to consider include:

1 - Is the water converted to an aerosol?

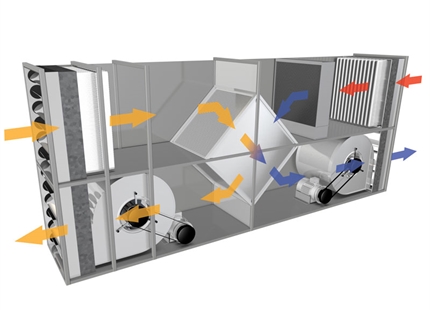

Legionella is transmitted in aerosols which have to be drawn deep into a person’s respiratory system. Any humidifier that produces an aerosol such as an atomising humidifier or ultrasonic mister, particularly if they spray directly in the air where people are present, is therefore a potential source of concern. However, modern, well-designed atomising spray systems such as the JetSpray, which incorporate a number of features designed to prevent the development of Legionella, will give many years of safe service when properly installed and maintained. Nonetheless, they must be included in a Legionella monitoring and control system as described in L8.

It is not just aerosol-generating humidifiers that need to be considered. Others, including steam and evaporative systems must be included in the water system risk assessment. For example, a self-generating steam humidifier, left standing out of operation but with a boiler full of water during the summer months, might well contain Legionella bacteria. If drained carelessly, an aerosol might be created from splashing which could be inhaled by the maintenance technician. Steam Humidifiers such as the Condair EL and Condair RS incorporate self-drain timers to automatically empty the unit when out of use, to help reduce this risk.

2 - Is there a risk of the water becoming stagnant?

Legionella thrives in stagnant water. Consideration should not only be given to the water in the humidifier itself but also to any water tanks and pipework supplying it. Oversized tanks mean slow water turnover. Pipework supplying a humidifier might lie dormant over the summer, acting as a deadleg. Systems should be designed to avoid this, to flush regularly, and drain or purge all water from the system when not in use for a predetermined length of time.

L8 recommends that water doesn’t remain static for more than 24 hours. Many of Condair's humidifiers incorporate daily flush-through and drain features to help minimize this risk. However, checking that these cycles are working should be included in your monitoring and control scheme.

3 - Is the temperature above 20°C?

Legionella bacteria breed most successfully between 20-45°C. In warm buildings, cold-water temperatures might rise above 20°C in tanks and pipes that supply humidifiers. Legionella could flourish and then flow into humidifiers and be disseminated in aerosols.

To help prevent this, many cold water humidifiers now incorporate a water disinfection system such as UV or silver ionisation. In the case of JetSpray, fail-safe UV is used so that, if the UV lamp blows or drops below its threshold of effectiveness, the humidifier will automatically turn off. However, a check on the good operation of the UV system should be included in your monitoring and control regime.

4 - Is there a source of nutrients in the water?

Dirty water, scale in pipes, slime or biofilm encourage Legionella by providing the right conditions to allow it to multiply. Some types of rubber, leather and some jointing compounds also provide nutrition, so it’s best to use PTFE-based materials for joints. Pipework and other components should be of materials that don’t support bacterial growth, such as stainless steel or food-grade plastics.

Water treatment, including water softeners and reverse osmosis (RO), are often used with humidifiers because they reduce scaling, and therefore maintenance. RO has the added benefit of filtering out bacteria and many other contaminants. However, once water is treated by RO it must be kept clean, as any residual purification chemical, such as chlorine, might also have been removed by a carbon filter, if present. As a safeguard, RO water should be irradiated by UV light or silver ion treatment, to maintain its cleanliness.

5 – High risk groups

The elderly and sick people are more at risk from Legionella than healthy adults. Care should be taken in selecting the right humidifier for such high-risk groups, so a portable atomiser shouldn’t be used in a hospital environment, for example, but a steam humidifier might be suitable.

Summary

This article is not exhaustive and should be regarded as no more than an introduction to the risk of Legionnaires’ disease in relation to humidifiers. Although outbreaks of Legionnaires’ disease are rarely associated with humidifiers, with correct risk assessment it can be eliminated altogether.

Each humidification system is different and one which is safe in one environment might create a hazard in another situation. For that reason, the L8 ACoP requires us to assess the risk in the particular situation in which the humidifier is used. Where legislation exists overseas, its requirements are typically similar. Always read the manufacturer’s installation and maintenance manual, and follow their instructions, but this alone is not enough. In assessing risk always take account of the water system as a whole and the people working near the humidifier.

It is essential that any individual nominated within an organisation to be the duty holder or responsible person for the control of legionellosis within their premises is suitably trained, that they familiarise themselves with any humidifiers in their buildings and fully understand their responsibilities with respect to Legionnaires’ disease. If in doubt, seek expert advice.

Useful links

More information on Legionnaires’ disease, L8 and other HSE publications can be found on the Health and Safety Executive's website.

Guidance is also available from the Chartered Institution of Building Services Engineers (CIBSE) publication TM13, Minimising the Risk of Legionnaires’ Disease.

Expert advice is available on the control of legionellosis and water system risk assessment advice through the Legionella Control Association and the Water Management Society.

Humidifier manufacturers and suppliers who are members of HEVAC’s Humidity Group will be pleased to advise on the safe application of their humidifiers, including Condair plc.