Benefits

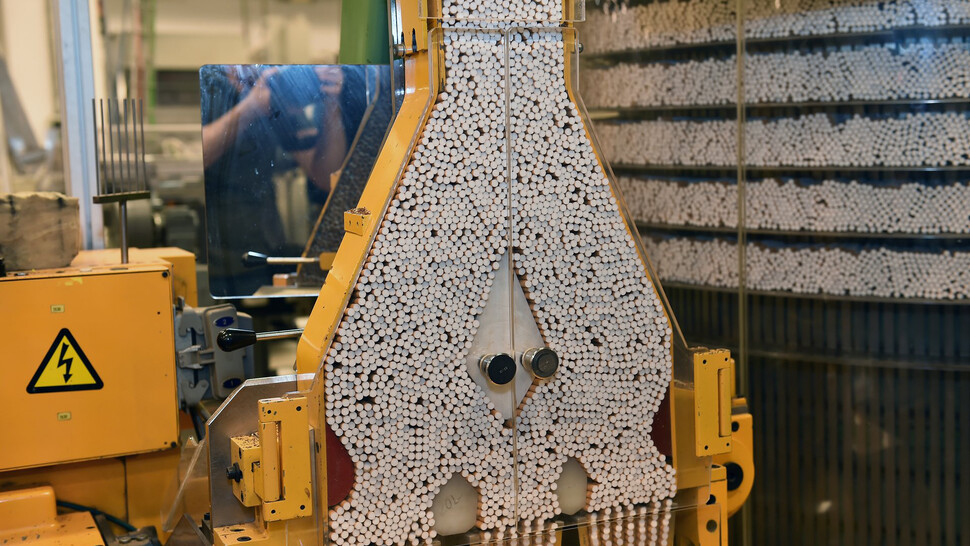

Tobacco leaves, cut tobacco and paper are all extremely hygroscopic which means that they give up their moisture to the surrounding environment if the air is too dry. Humidification is critical for success.

Reduce weight loss

If tobacco loses weight, it's market value is reduced, minimising profits.

Maintain quality

Dry air causes tobacco's properties to degrade resulting in brittleness, flaking, splitting and tearing.

Maximise production efficiency

Reduced wastage maximises production and processing speeds.

Optimal tobacco quality

Minimise static

Innovative solutions for unique processes

Downloads

Download an application brochure giving a detailed look at the importance of humidification in the tobacco industry.

Application brochure

Frequently asked questions

What is the ideal humidity level for tobacco manufacturing?

Why is humidity control important in tobacco production?

What happens if humidity falls below 50%RH?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.