A cool recovery with humidifiers

Dave Marshall-George, Sales Director at Condair UK, explores how evaporative humidifiers can significantly reduce HVAC energy consumption, increase sustainability and minimise operating costs.

Recovering heat from a building’s extract air is a well-established method for reducing HVAC energy consumption during the winter. However, recovering thermal energy for cooling in the summer also offers huge potential. It is a greatly underused strategy and is currently nowhere near as well understood by building services engineers as its heat-recovery cousin.

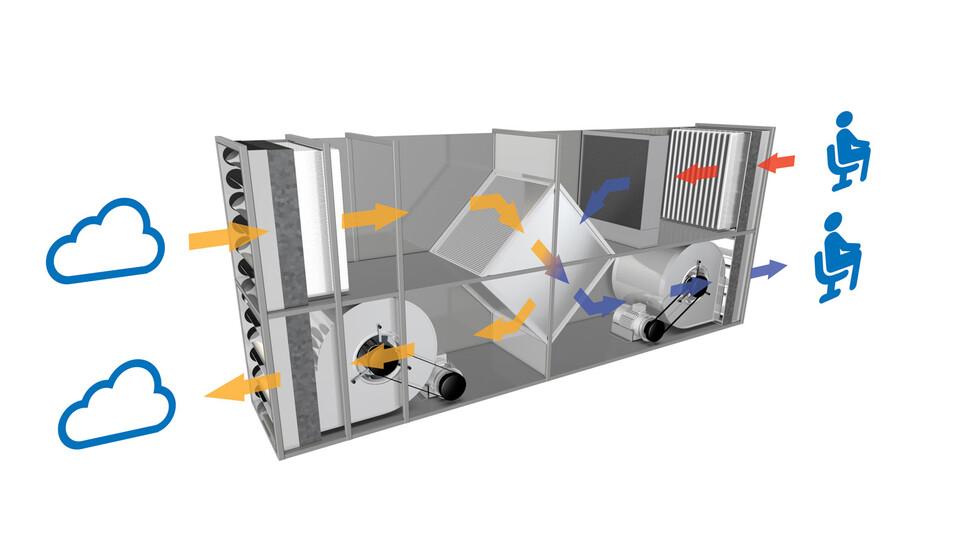

Now given the relative similarity in temperature between incoming and outgoing summer air, you might think that warm extract air from a room offers little potential for cooling incoming air, other than on the hottest of days. And by itself, you’d mostly be right. However, by adding a low energy, evaporative humidifier to the exhaust airstream prior to an energy recovery system, the temperature of the extract air can be greatly reduced. This increases the potential for energy recovery from outgoing to incoming airstreams in the summer, allowing for up to 10K of very low energy cooling to be achieved.

There are typically two main limitations for using evaporative humidifiers to cool in a HVAC system when used directly on incoming air. Firstly, the cooling capacity of the humidifier is dependent on the condition of the fresh air going on to the humidifier. Air with a high humidity prior to the humidifier will not absorb much water. So, without much evaporation, the resultant cooling can be limited, and this will vary depending on the outside weather. However, with an exhaust air cooling strategy, the condition of the air going on to the humidifier is always relatively consistent. The room’s extract air condition rarely has a high humidity, allowing good potential for evaporation.

The second limitation for direct air evaporative cooling is the maximum allowed humidity after the humidifier. This is dependent on the supply air condition to the room. Air that is too humid will not be comfortable and could cause issues with a building’s fabric. So, if the maximum allowed humidity to the room is 55%RH, then the capacity for direct evaporative cooling is limited to this level.

But, when positioning the humidifier in the exhaust air duct, to humidify the air in the extract airstream, the maximum room humidity limitation is irrelevant. The humidifier can saturate the extract air with maximum cooling effect. This wet cool air is then run through an energy recovery system and subsequently vented externally. As the air is significantly cooler after the humidifier, there is much greater difference between outgoing and incoming air temperatures, and therefore more potential for the consistent transfer of cooling to the incoming air.

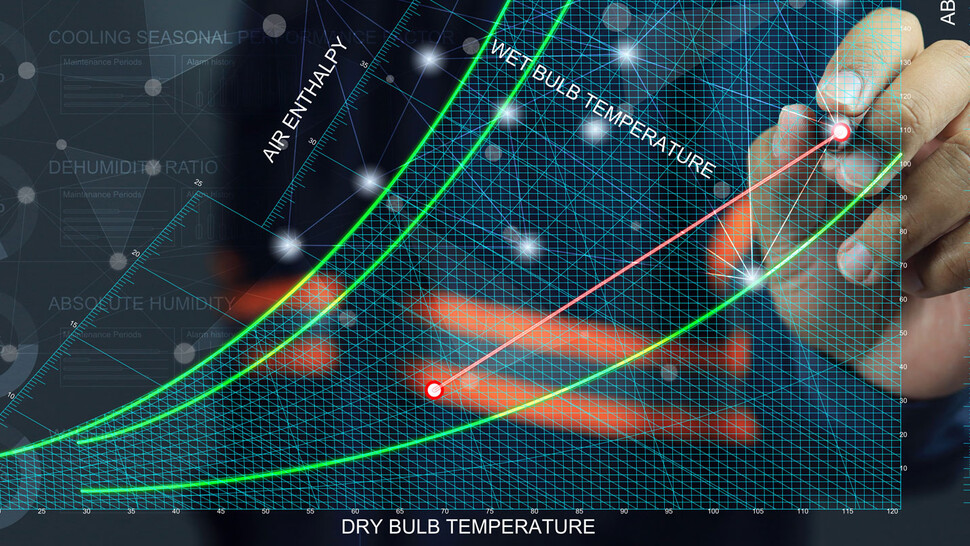

To put some figures against this potential, if the air extracted from the room is 21°C and 50%RH, and is humidified to 95%RH, a run-around energy recovery system with a 90% efficiency could pre-cool incoming air of 28°C and 44%RH by up to 11°C. This level of cooling would significantly reduce a building’s HVAC energy consumption during the summer. It may not always replace the need for mechanical cooling, but it will greatly reduce the size of chiller needed and the ongoing energy consumption for mechanical cooling. This will lower a building’s carbon footprint and improve its sustainability.

A recent successful illustration of this strategy can be seen in a new-build health clinic in Tyrol, Austria. Condair worked with energy recovery specialist, Konvekta, and supplied its Condair ME evaporative humidifiers. They cooled the extract air prior to it being run through Konvekta’s high efficiency run-around energy recovery systems.

Amir Ibrahimagic, Group Business Development Manager at Konvekta, explains, “Hospitals, research labs, and universities have a particularly high interest when it comes to energy recovery systems because they have extensive operational times, leading to high energy costs. With a good energy recovery unit, they can massively decrease their energy use. For this project in Hull in Tyrol, we installed three energy recovery units with Condair ME evaporative humidifiers. Overall, ongoing monitoring showed a proven annual energy recovery of 92% on an annual basis across all Konvekta systems.

“A single Condair ME humidifier contributed more than 60,000kWh of cooling during this annual period from just 3,800kWh of consumed electricity. This low energy cooling significantly improved the building’s overall energy efficiency and helped our client become the most sustainable clinic of its type in all of Austria.” Amir concluded.

For designers who want to know how much cooling would be available using this exhaust air evaporative cooling strategy for a specific project, Condair can utilise worldwide weather data from over 300 locations and allows variable AHU configurations to be set.

Accurate calculations are provided for the amount of exhaust air cooling that will be delivered, alongside mechanical, in different climates and under different building operating conditions. For instance, a building in London with a room set point of 22°C, operating during office hours only, with a 3x3m evaporative humidifier and 3m/s airflow, could meet 55% of its annual cooling needs with exhaust air cooling. Whilst the same building in Sydney, Australia, would be able to achieve 36% of its cooling in the same way.

As room conditions are relatively consistent in air-conditioned buildings around the world, the strategy of exhaust air cooling is universal. Exhaust air evaporative cooling is a proven and effective strategy, and if more widely understood and applied, could help our industry take a further step towards its net zero goals.

Read the full article as it appeared in BSEE magazine June 24.

Find out more about Condair's full range of evaporative cooling solutions and reach out to the team for more information.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.