Electrode vs resistive steam humidifiers

Electrode and resistive are the two main types of electric steam humidifier a HVAC contractor will buy and install. Both are versatile and come in a variety of sizes for either in-room or in-duct applications.

From a contractor’s perspective the main considerations when selecting a unit are often purchase cost and ease of installation. For a customer or end-user the initial cost is also important but so are on-going operating costs and maintenance requirements.

The main differences between electrode and resistive technologies are how they heat the water to create steam and how they control steam output.

The electrode boils water by passing electrical current through it. The more current passes through the water, the greater the steam production. So output increases with a higher water level or when higher mineral levels make the water more conductive.

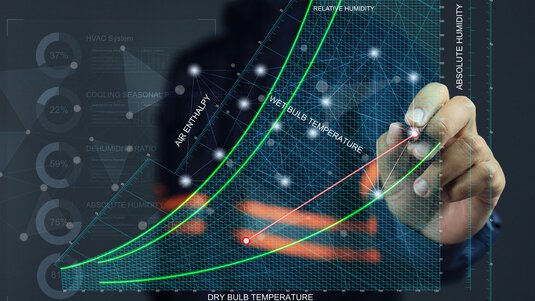

To maintain an accurate output, the concentration of minerals in the water is regulated through drainage and replacement with fresh water. This typically allows for humidity control of around +/-5%RH.

Resistive humidifiers create steam through the transfer of heat from the resistance heater elements to the water. Steam output is controlled by applying more or less heat to the water rather than controlling water level or conductivity. This results in more accurate humidity control of around +/-2%RH with mains water.

As the mineral content of the water has no impact on steam output, resistive humidifiers can also operate on RO water. As the mineral content of the water is very low, this virtually eliminates scale build-up, significantly reducing maintenance requirements.

It also improves humidity control by removing the need for fresh (cold) water to be regularly introduced to reduce mineral levels. A consistent water temperature results in a consistent steam output and enables a resistive humidifier operating on RO water to control humidity to +/-1%RH.

Electrode humidifiers tend to have the lowest capital cost of the two technologies. Installation costs for both electrode and resistive are comparable plus both are simple to install as they require connection to power, water mains supply and drain only.

The cost of operating a steam humidifier is largely determined by two things. The energy required to turn water from a liquid to a gas and the cost of dealing with what’s left behind in the humidifier after this has happened.

When run on mains water, the energy costs are the same for both humidifiers, as they use the same amount of electricity to create the steam. However, if the resistive unit is run on RO water, electrical consumption is less as very little hot water is sent to drain. Although energy consumption is improved by the use of RO water, water consumption is increased as 50% of the water is sent to drain as part of the initial filtration process.

With an electrode boiler, as steam is produced, any minerals in the water build-up within the plastic cylinder as limescale. When these cylinders are full of limescale they are replaced, which is straightforward and offers the benefit of very rapid maintenance and minimal downtime for the humidification system. The disadvantage is that cylinders can be expensive and represent an on-going spares cost.

As resistive steam humidifiers do not pass current through the water they can operate with stainless steel boiling chambers that can be cleaned rather than replaced. This avoids the expense of disposable cylinders reducing spares costs. So much so, that the initial cost of the more expensive resistive unit can be recouped within 18 months.

So although on-going operating costs can be less with a resistive humidifier, servicing takes longer as the unit needs to be emptied of scale. However, some advanced systems, such as the Condair RS resistive steam humidifier, reduce this service burden through innovative scale management features. An external scale collector allows limescale to be removed quickly and easily without needing to open the main body of the humidifier, greatly reducing service time.

As we’ve seen, both technologies have advantages and disadvantages and the choice of system largely depends on the end-user’s needs. If very close humidity control is needed resistive humidifiers with or without RO water could be the best option.

If close humidity control isn’t important, but simple maintenance with minimal downtime is, an electrode boiler with its replaceable cylinders could suit. But if a customer wants the lowest whole life cost across capital, service and consumables, then a resistive humidifier will provide this.

Read this article as it appeared in ACR Journal September 15.

How to select and size a commercial humidifier

Dave Marshall-George, Sales Director at Condair, explains what should be considered when setting out on a humidifier project.

He describes the main elements that determine whether a humidifier should be used in an AHU or directly in a room, which type of humidifier fits what type of application and how to correctly size a unit for an area.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.