Summary

Correct positioning essential

Steam humidifiers should be installed as close to the air handling unit (AHU) as possible.

Steam must be fully absorbed

The steam lance must be positioned so steam is fully and evenly absorbed by the airflow without wetting.

Correct installation vital for longterm reliability

Incorrect installation can lead to inefficiency, poor humidity control and short operational life.

How to install a steam humidifier

Tony Tullett, Service Director at Condair Limited, provides some best practice guidance on steam humidifier installation

The most common humidifier any HVAC contractor is going to come across is a self-generating, electric steam humidifier. These will typically provide steam to an air handling unit but are also available for direct room humidification with a fan unit. However, for the sake of this guide, I’m going to focus on AHU humidification, as this is the most common.

Electric steam humidifiers are available with either resistive or electrode boiler technology. A resistive humidifier heats the water with a kettle-like element, whilst an electrode boiler passes current through the water. The maintenance needs of both types differ substantially but the installation requirements are identical.

The main equipment consists of the humidifier itself, which is typically attached to a wall, a length of steam pipe running from the humidifier into the AHU, and finally a steam lance attached to the end of the steam pipe that releases the steam into the duct’s airstream. Associated elements could include sensors, humidistats, water treatment systems and potentially water pumps and tanks.

Firstly, the steam humidifier needs to be located as close to the AHU as possible. This is to maintain efficient transfer of the steam from the boiling cylinder to the airstream. Long runs of steam pipe, with associated bends, will increase condensation in the pipework. Heating water to create steam, only to allow it to condense back to water again, is a waste of energy. It could also mean the steam output of the system is reduced, resulting in it not being able to meet the required demands of the building. The steam pipe should be a maximum of 4m, with each bend reducing this length by 1m.

The humidifier will require connections for power, water supply and drain. It is important the humidifier is not located directly above the drain. With drain water released at up to 100°C, steam can rise and condense on and inside the humidifier’s cabinet, potentially causing corrosion.

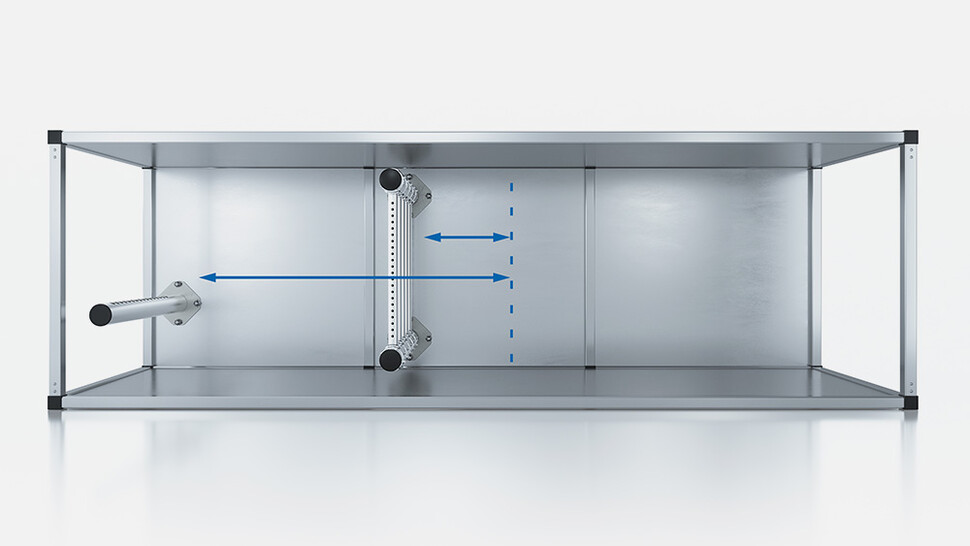

When positioning the steam lance inside the duct, the main objective is to ensure the steam released is fully and uniformly absorbed by the airflow, without any wetting inside the duct or onto any elements downstream. To achieve this, a single lance is typically placed around 1/3 of the duct height from the floor and should protrude at least 75% across the duct width. This gives optimum conditions for the steam to be released without touching the walls or ceiling. It is important to maintain a minimum distance from the floor of 85mm and 165mm from the ceiling. This is to avoid creating turbulence that could direct the steam onto the ductwork, resulting in condensation. The minimum duct height a steam lance can be used in is therefore 250mm.

The steam lance will need at least 300mm clearance before it, without any corners, transitions or t-branches in the duct. This is again to avoid turbulent and non-laminar airflow directing the steam onto the walls or ceiling.

Steam absorption distance

The required clearance distance after the steam lance will depend on the absorption distance of the steam. To avoid condensation, nothing should be located in this absorption area, with no duct bends or transitions. This absorption distance is calculated factoring in the temperature, humidity and velocity of the airstream, and the length, number and type of steam lance.

To give an example, at 2.5m/s, 20°C and 50%RH, the absorption distance will be around 1m with standard steam lances. However, this can be shortened by up to 70% with the use of advanced short evaporation steam lance manifolds. The humidifier supplier ought to be able to provide an exact absorption distance, given the project’s specification.

If submicron filters are used after the humidifier, the clearance should be 2.5 times the absorption distance to avoid moisture being removed by the filter. If sensors or high-limit humidistats are placed in the duct, the clearance should be five times the absorption distance, to ensure proper mixing prior to the stat. Ideally sensors should be placed in the return air duct, to provide accurate control feedback on the room condition.

Another thing that an installer ought to consider is the installation of a drip tray under the steam lance in the duct to protect against corrosion. Also, all humidifiers need to be serviced, so clear access to the humidifier is essential.

Finally, it is always recommended that the humidifier manufacturer ought to carry out the commissioning of the unit, to ensure the equipment is installed correctly, with optimum controls set-up and operational performance.

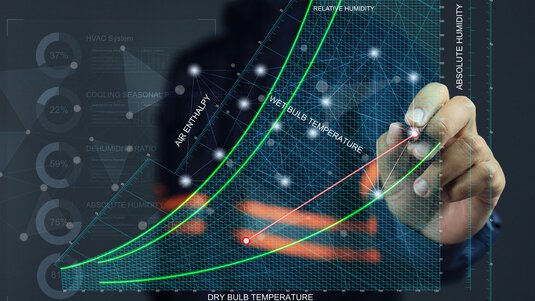

Get a free 10-point guide to humidifier specification

Download your 10-point guide to specifying humidifiers and get an easy-to-follow overview for planning humidifier projects.

It covers topics such as psychrometrics, product sizing, technology selection, installation considerations and hygiene management.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.