Benefits

Maintaining ideal conditions in conveyor systems requires precise humidity control. Fluctuations can affect product quality and process reliability.

Prevents adhesion

Avoids materials sticking to conveyor belts or rollers due to high humidity

Enhances safety

Reduces the risk of slippage or malfunction caused by moisture on conveyor systems

Stable quality

Keeps conditions stable for consistent product quality

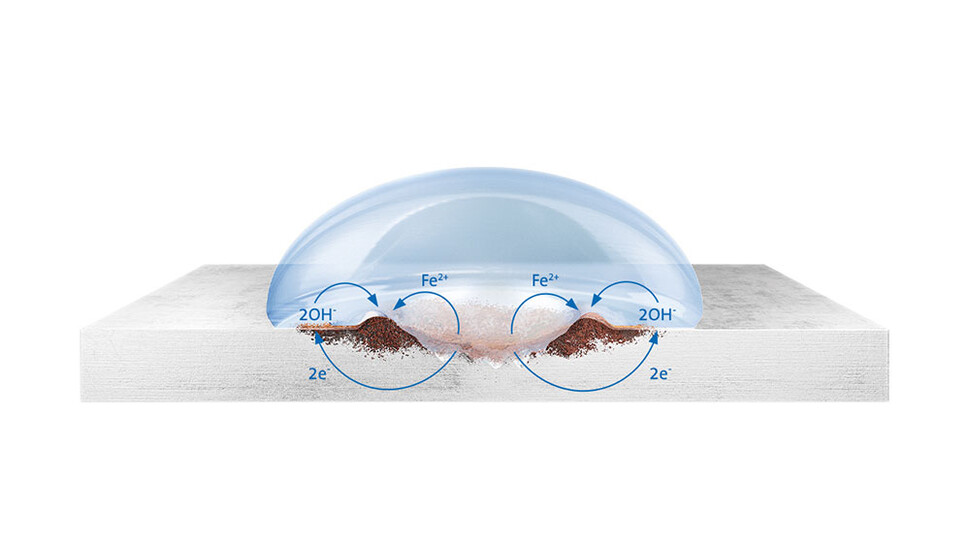

Preventing corrosion on conveyor systems

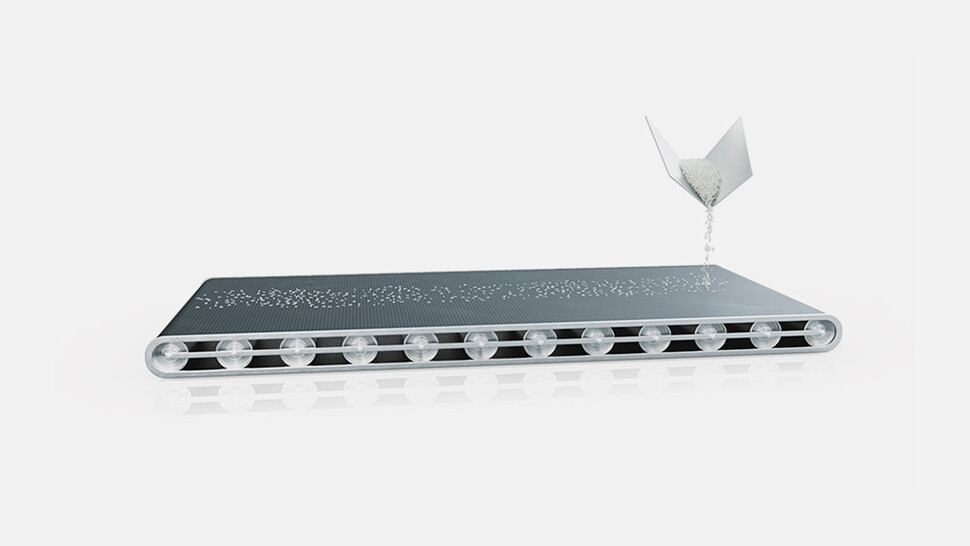

Keeping bulk material pourable

pre-dehumidifying the air prevents sticking or lump formation during transport. Modern adsorption dryers ensure reliable material flow from silo to storage, maintain processing quality, and reduce cleaning costs.

Preventing general cargo from adhering to conveyor belts

Use cases

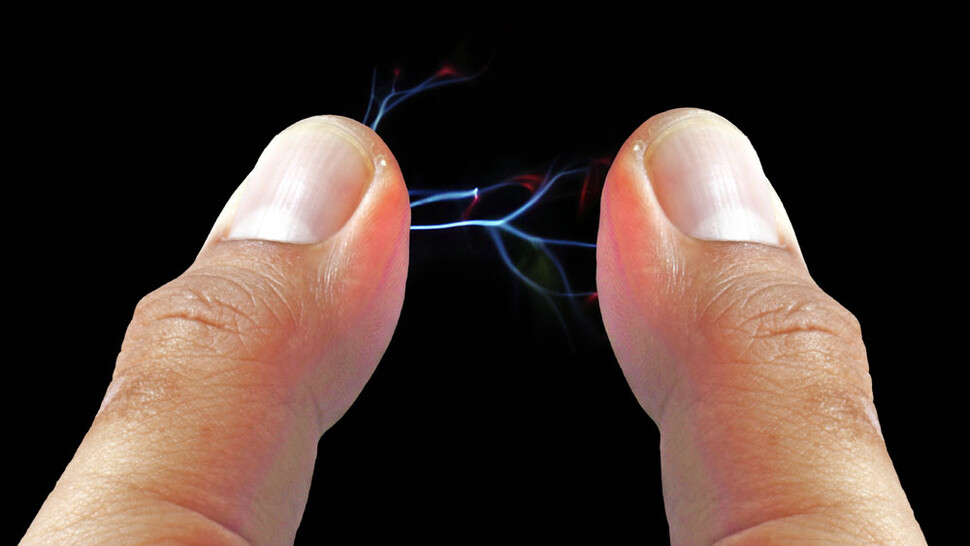

Anti-static and ESD prevention

Prevent condensation and mould

Humidification solutions for dust and odour reduction

Frequently asked questions

What are the benefits of integrating dehumidifiers into conveying technology operations?

Which dehumidification technologies are used in conveying technology?

Why is dehumidification needed in conveying technology for food processing?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.