Benefits

Humidification systems provide an effective means of meeting required limits, improving process flows and safeguarding the health of employees in many industries that produce significant dust and/or odour emissions.

Dust suppression

Adequate humidity cleans the air of dust faster, reducing the risk of fine dust getting into the respiratory tract.

Odour containment

In addition to binding dust particles with air humidification, odour particles will be suppressed as well.

Observing limit values

Dust is swept up into the air as particle matter in waste incinerator plants, quarries, sorting and shredder plants, which is then carried into the ambient air as airborne dust.

Dust suppression in the wood working industry

Humidification systems using fine spray nozzles effectively suppress airborne dust in woodworking environments. By increasing relative humidity, dust particles become heavier and settle more quickly, improving air quality, machine performance, and worker safety.

Dust suppression in the textile industry

Humidification with fine spray nozzles helps suppress airborne fibres and dust in textile production. The added moisture binds loose particles, improving air quality, reducing static, and supporting smoother processing.

Dust and odour suppression in waste disposal facilities

Odour and dust suppression is beneficial in many industries and applications

Frequently asked questions

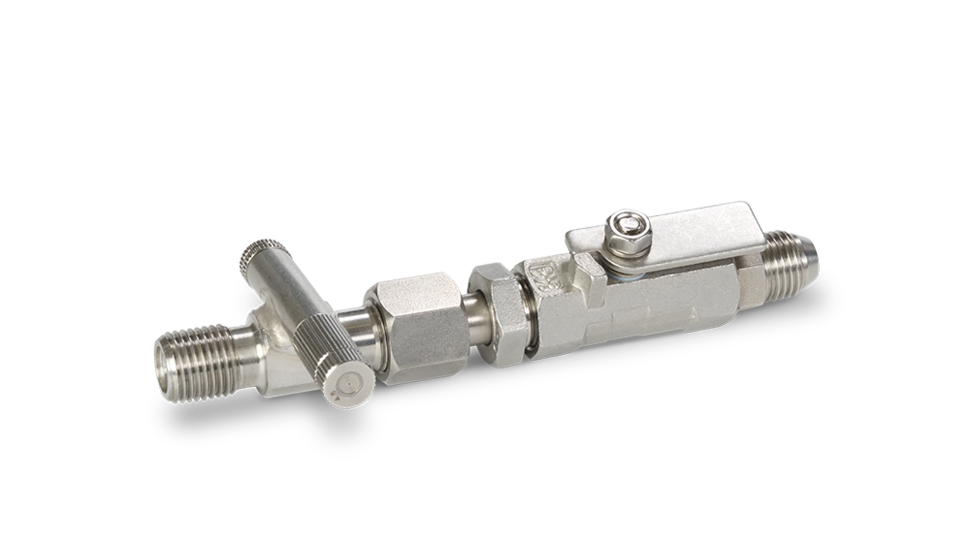

How does high-pressure nozzle humidification reduce dust levels?

How does maintaining optimal humidity help prevent dust formation?

What makes high-pressure systems better than traditional humidifiers for dust control?

Why is high-pressure mist effective for controlling odours?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.