Benefits

Stable relative humidity prevents paint from drying too fast or too slow and ensures a better levelling, reduced orange peel, and consistent colour tone across batches.

Superior paint quality

Maintaining stable RH ensures flawless finishes, prevent defects and delivers consistent colour and coating performance across all production conditions.

Reduce rework, waste, and downtime

Optimised moisture levels minimise paint booth faults, cut rework by reducing defects, and create smoother, more efficient spraying operations.

Coating stability

Humidity regulation eliminates seasonal variation, ensures predictable curing, and keeps surface-finishing quality high every day of the year.

Improved paint flow, finish quality and colour consistency

Better environmental and worker conditions and consistent process conditions year-round

Use cases

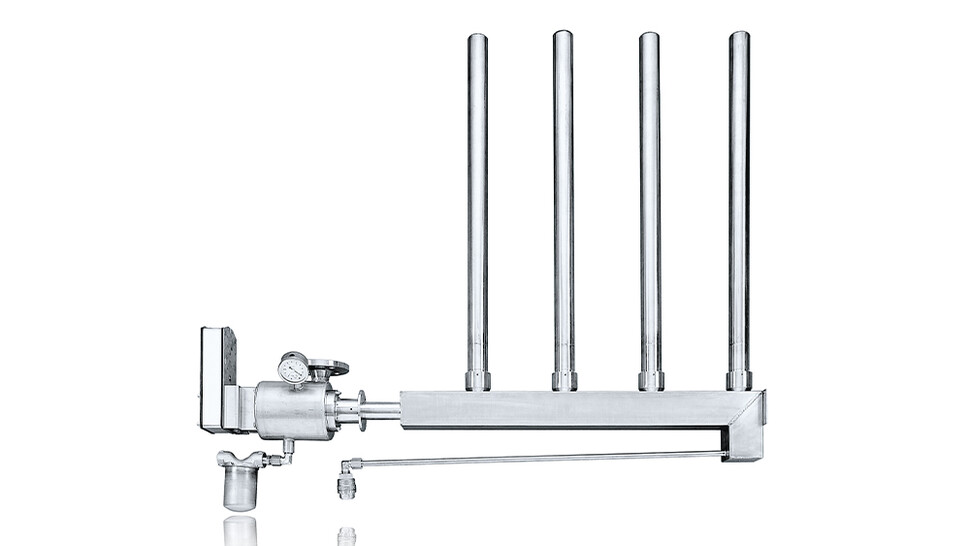

Prevent evaporative losses

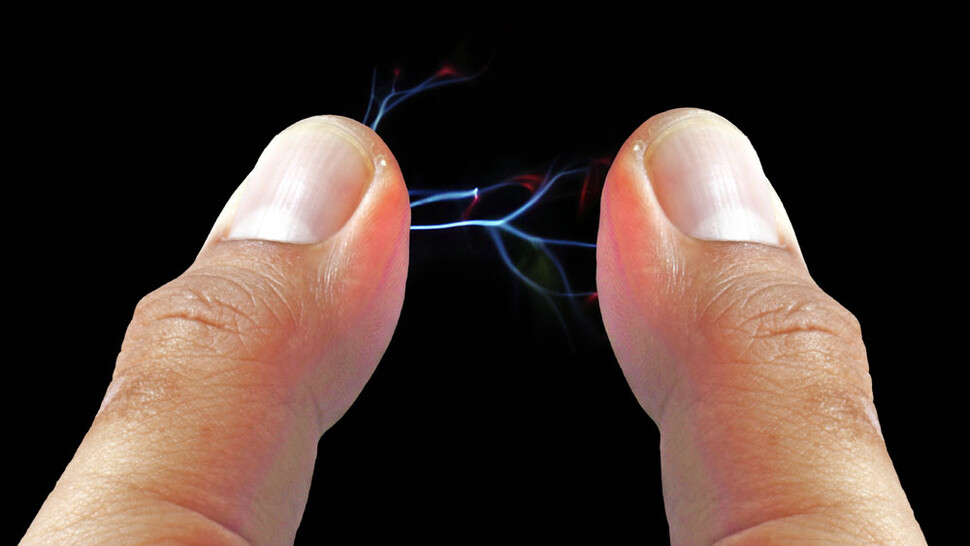

Anti-static and ESD prevention

Frequently asked questions

Why is humidity control important in a paint spray booth?

How does humidity control reduce rework and production costs?

What problems occur when humidity is too low?

What happens if humidity is too high during painting or finishing?

Do both water-based and solvent-based paints require humidity control?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.