Steve Freeman

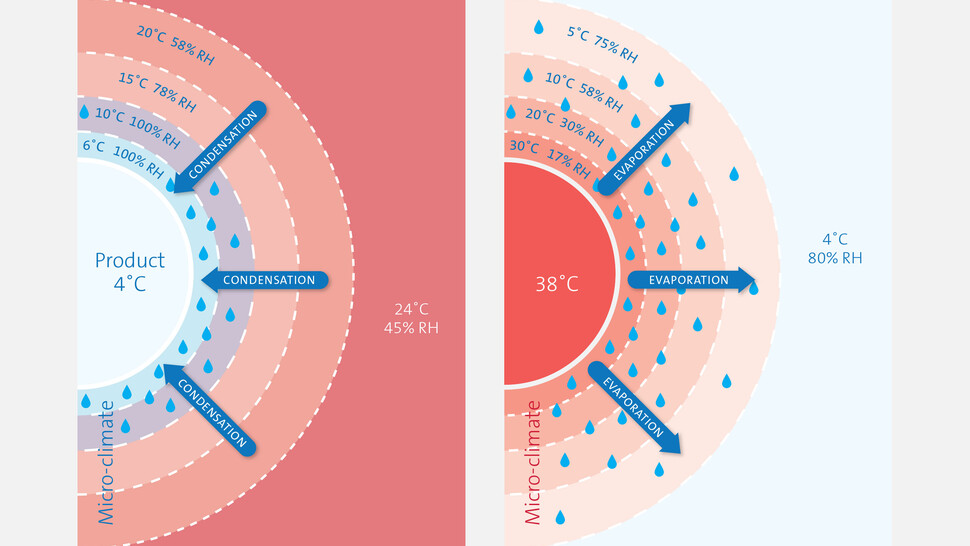

Jet Press Solutions ManagerHumidity control is important for paper handling consistency when running lighter weight stock on the Jet Press 720S in both the feeder and jetting area. We aim to maintain an RH of between 40% and 60%. Below this could potentially cause an increase in paper handling issues on light weight paper.

Once the humidifier was up and running correctly, it has performed well. It now easily and quickly gets the room up to the required RH and maintains this after start-up.

Once the humidifier was up and running correctly, it has performed well. It now easily and quickly gets the room up to the required RH and maintains this after start-up.