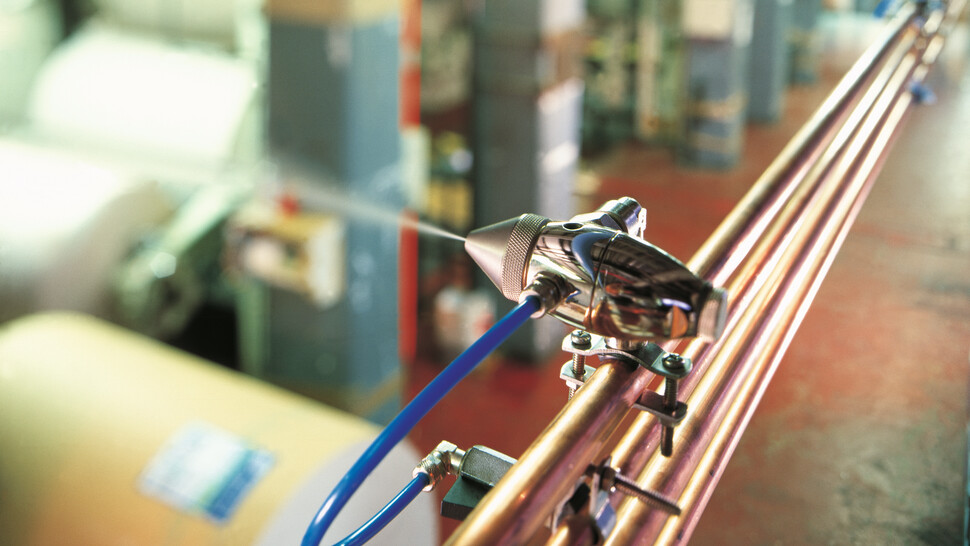

JetSpray panel

An IP54-rated cabinet provides convenient access to nozzle controls, with all electronics stored separately above the water and air pipes.

Download your 10-point guide to specifying humidifiers and get an easy-to-follow overview for planning humidifier projects.

It covers topics such as psychrometrics, product sizing, technology selection, installation considerations and hygiene management.

Contact the UK office by phone, email or webform.

If you're outside the UK, find your local representative.