Control of the cleanroom environment

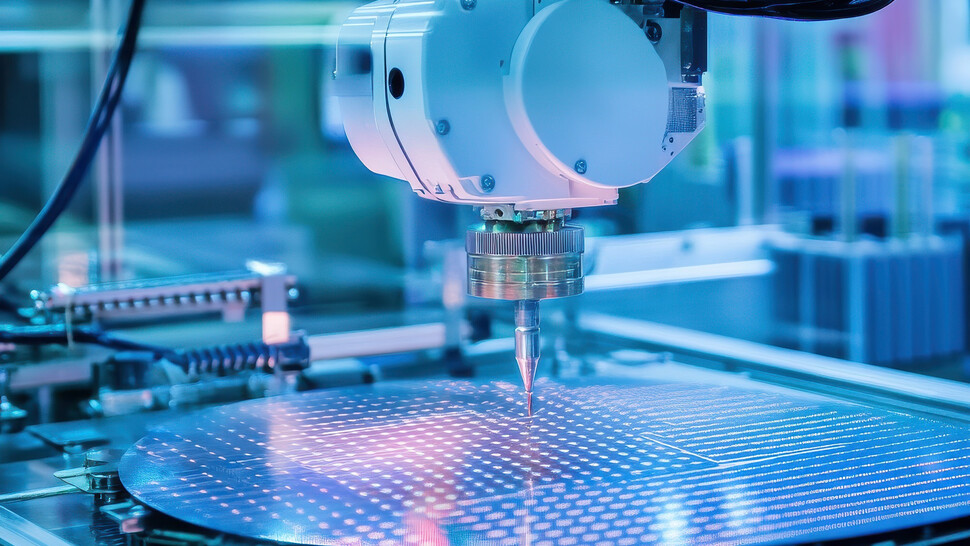

Semiconductors and their manufacturing processes are highly sensitive to humidity levels. Insufficient, excessive and inconsistent humidity levels causes damage and defects. Complete control of indoor air conditions is required.

Maintain optimal conditions

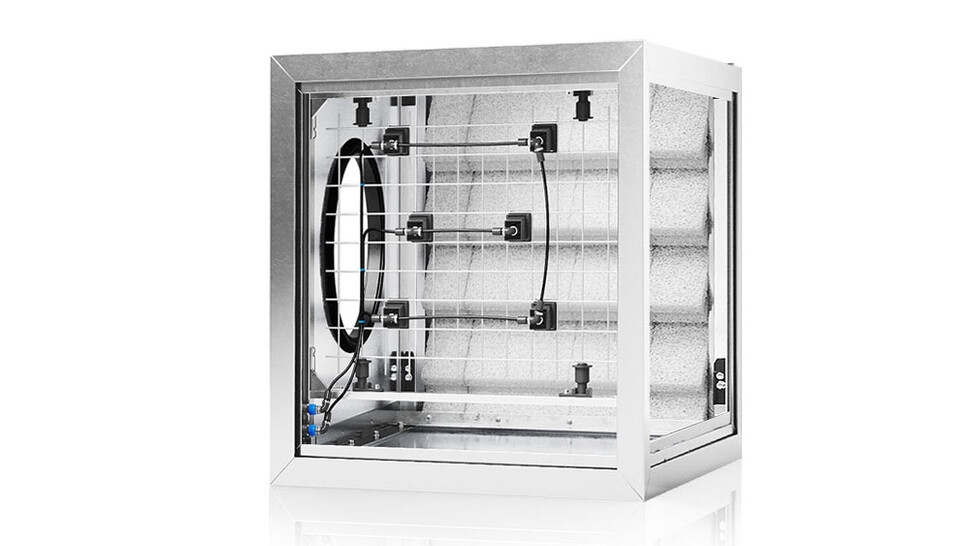

All semiconductor manufacturing processes have to be tightly controlled and so will nearly always take place in a cleanroom environment. Precise control of humidity against set point and stability over a time period is a fundamental requirement.

Minimise failures

A failure at any point during semiconductor manufacturing can be extremely expensive. Humidity control is absolutely necessary for consistent and reproducible production environments.

Absolute quality

The semiconductor industry relies on the highest quality products, materials and processes. Humidity control is a critical part of this.

Prevent photoresist dimensional changes

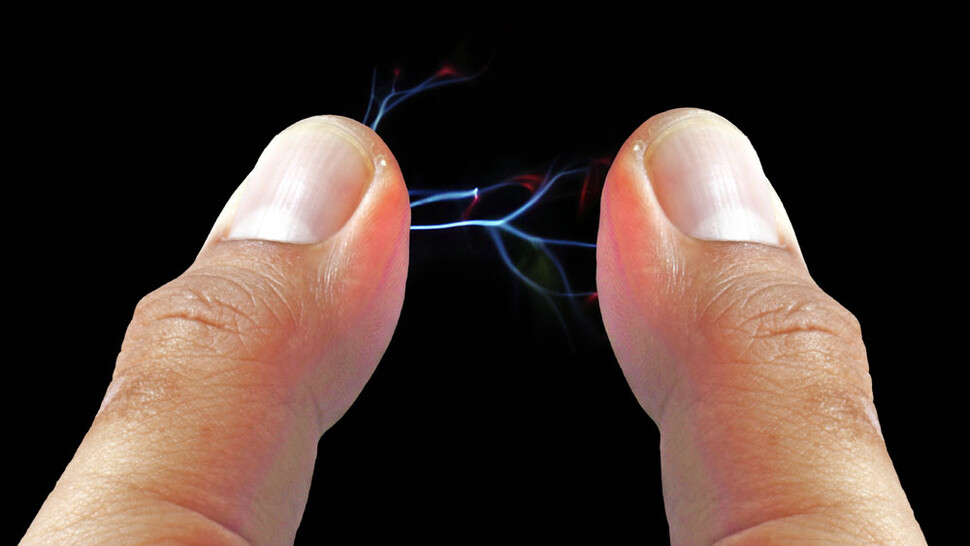

Humidification - the ideal solution to eliminate ESD

Enhanced indoor air quality and comfort for employees

Custom solutions for unique processes

Use cases

Anti-static and ESD prevention

Reliable operations start with a controlled environment

Indoor evaporative cooling with humidification

Frequently asked questions

Why is humidity control important in semiconductor manufacturing?

What is the ideal humidity level for semiconductor environments?

How does humidity control impact cleanroom standards?

What precision humidity control tolerances can be achieved?

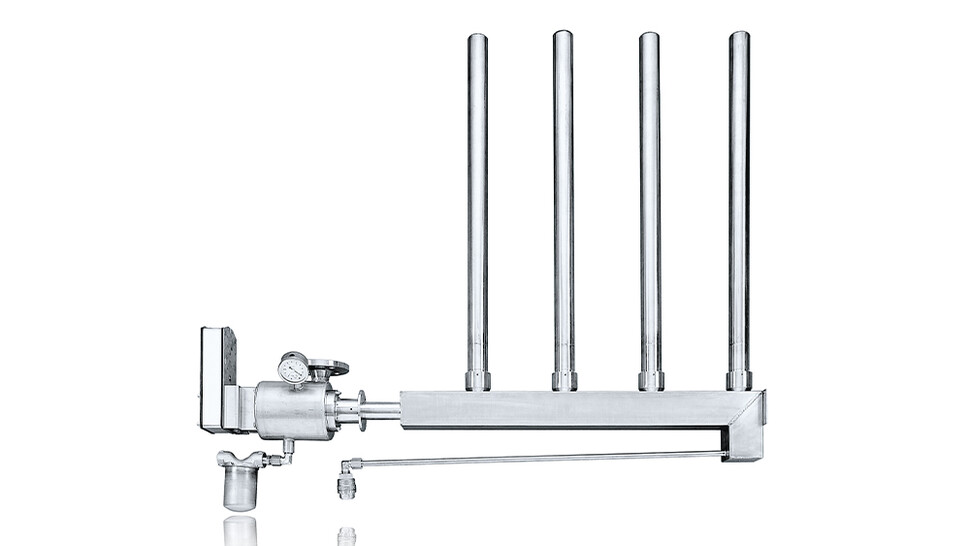

What types of humidifiers and dehumidifiers are suitable for semiconductor manufacturing facilities?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.