Benefits

Condair humidifiers and dehumidifiers ensure ideal humidity in electronics manufacturing, preventing ESD damage, protecting product quality, reducing dust and improving employee health.

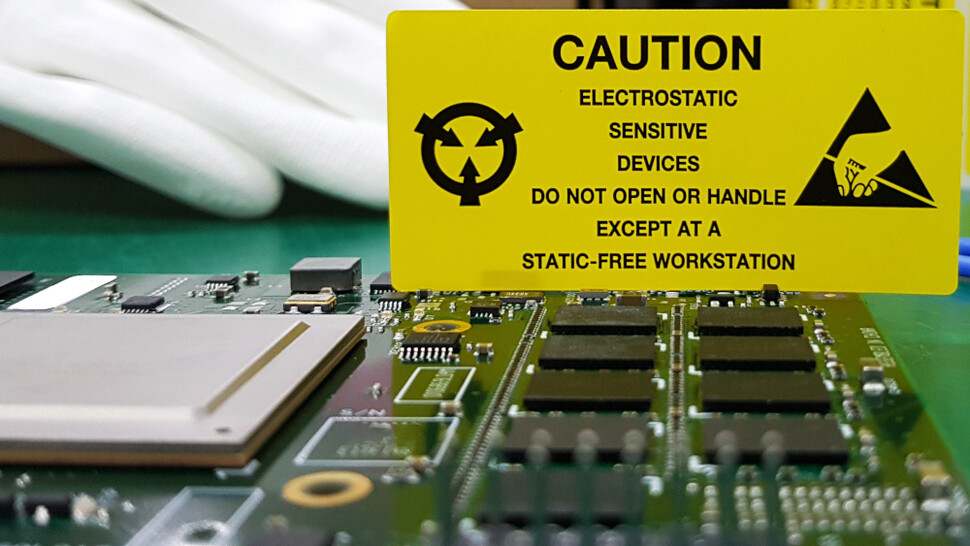

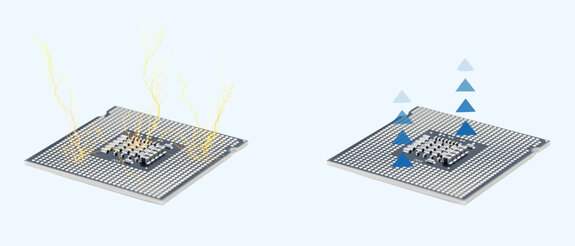

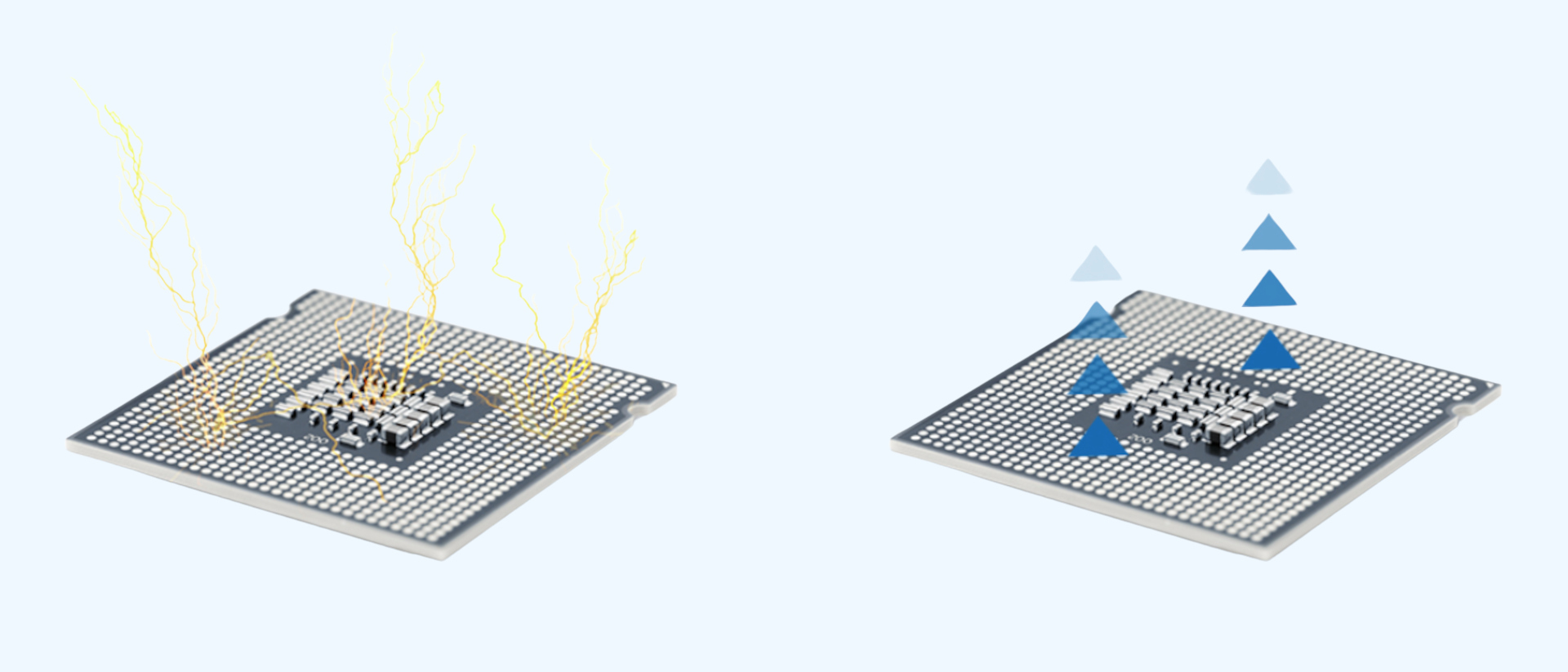

Reduce electrostatics (ESD)

Additional air humidification reduces electrostatic charges and protects sensitive components.

Standardised soldering

Controlled humidity protects against faulty soldering processes and solder joints.

Moisture damage protection (MSD)

Protection of moisture-sensitive components (MSD) during storage and in the manufacturing process.

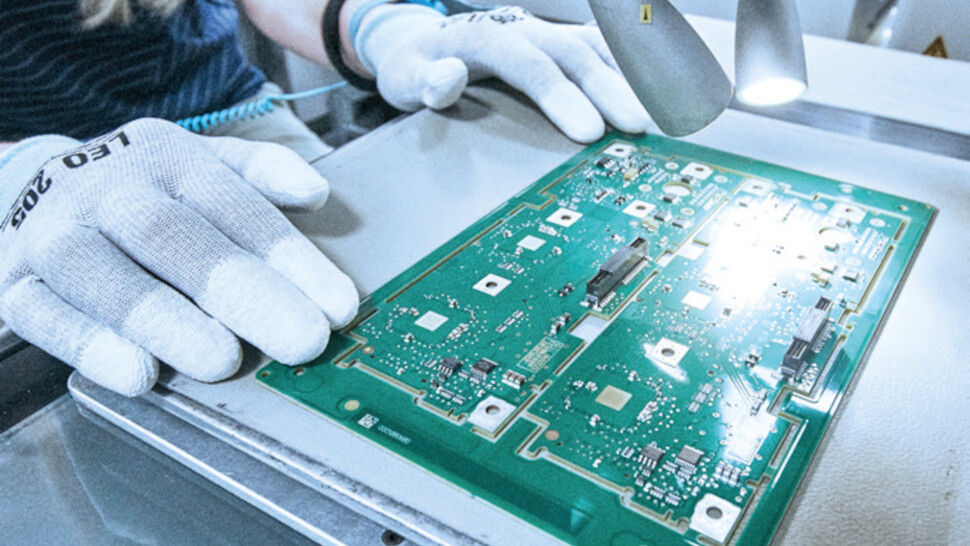

Humidification protects the electronics industry

Optimal humidity also ensures the quality of printing of the PCB, bonding and soldering processes in electronics manufacturing and guarantees reliable test results. If the humidity is too low, for example, the solder paste can dry too quickly, which impairs the strength of the solder joint and jeopardises the quality of the end product. In addition, optimum air humidity binds dust, improves the indoor climate, increases well-being and protects the health of employees from mucous membrane irritation and infections. Precise humidification therefore makes a significant contribution to process reliability, product quality and health protection.

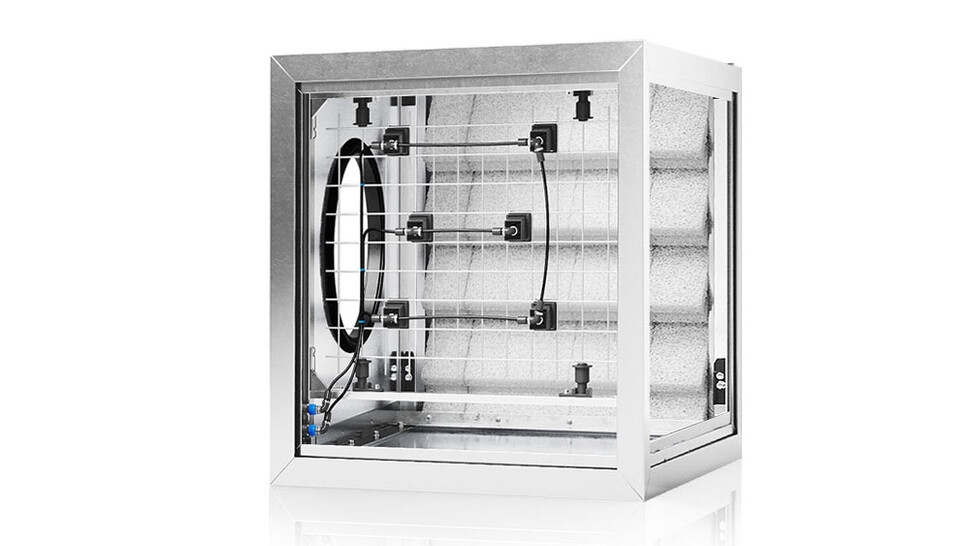

Dehumidification for electronic manufacturing

Dehumidification protects MSDs from these risks and maintains their functionality. In the manufacture of printed circuit boards. The viscosity of the photoresist is crucial for the precise placement of the conductor tracks. Excessive humidity reduces viscosity, thereby affecting the thickness of the applied coating and potentially leading to faulty conductor tracks. In soldering processes, excessive humidity can also reduce the viscosity of the solder paste to such an extent that it flows away from its intended position.

Energy-efficient cooling in the electronics industry

Evaporative cooling improves thermal stability in production rooms and prevents temperature-related quality fluctuations in the processing of solder pastes, photoresists and adhesives. The technology supports a constant ambient temperature, reduces thermal stress and at the same time improves the indoor climate for employees – a benefit for productivity, well-being and health.

ESD Protection

Use cases

Precise humidity control protects against ESD, prevents condensation and ensures an optimal, healthy indoor climate in electronics manufacturing through evaporative cooling.

Anti-static and ESD prevention

Prevent condensation and mould

In-duct evaporative cooling

Discover Condair in action

Frequently asked questions

Can controlled humidity improve soldering and bonding?

What is the ideal humidity level for ESD protection?

Why is humidity control so important in electronics manufacturing?

Does additional air humidification reduce dust formation?

Why are dehumidifiers used in electronics manufacturing?

Can humidifiers help to reduce process heat?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.