Benefits

Humidity fluctuations can cause static discharge, material distortion, and premature wear on sensitive equipment—all leading to costly downtime. By maintaining consistent humidity, you protect both your machinery and the materials they process, ensuring smoother production, fewer interruptions, and maximum operational uptime.

Protect sensitive equipment

Maintaining stable humidity prevents static electricity, reduces wear on mechanical and electronic systems, and helps avoid malfunctions. This leads to fewer breakdowns and longer equipment life.

Preserve material integrity

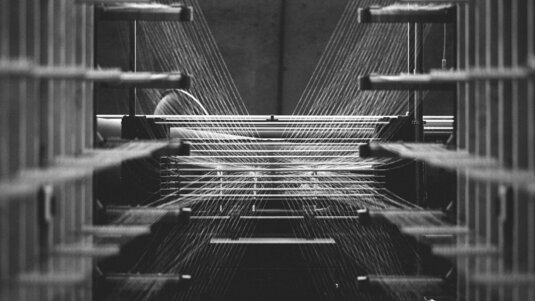

Controlled humidity prevents distortion, warping, or shrinkage in materials such as paper, wood, textiles, and composites. This ensures consistent quality and reduces production interruptions caused by material issues.

Reduce maintenance

By creating a stable environment, humidity control minimises unplanned stoppages and the need for frequent maintenance. This keeps production running smoothly and maximises operational uptime.

Humidity control protects equipment

Protect materials with humidity control

Maximise manufacturing uptime with humidity control

Discover Condair in action

Frequently asked questions

What happens if humidity levels fluctuate in a production environment?

How does humidity control support quality assurance?

How does humidity control improve machine uptime?

How can a facility determine whether improved humidity control is required?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.