Benefits

Controlled humidity protects against electrostatic discharge and ensures dimensional stability in the production and printing of cardboard, labels and films. Energy-efficient cooling of large halls ensures optimal production conditions and cost savings.

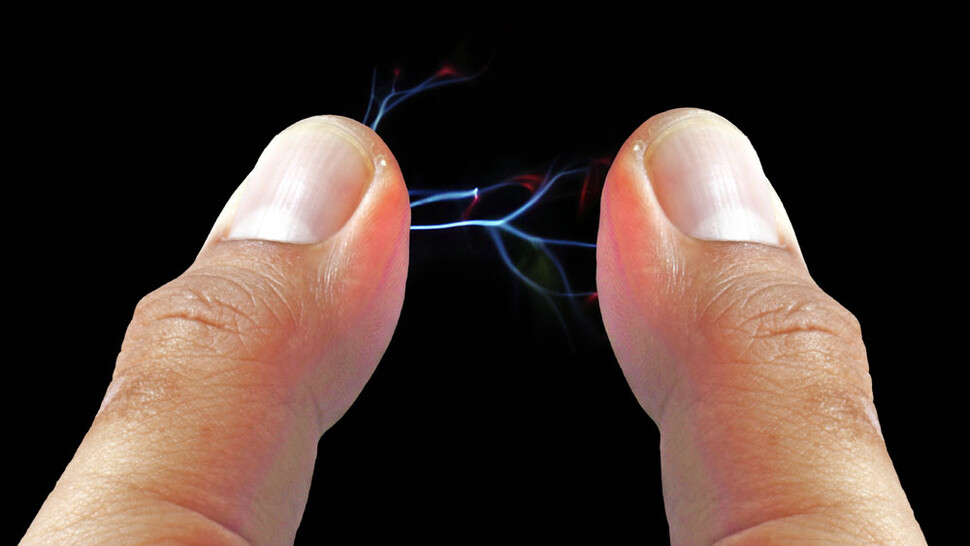

Reduce electrostatic

Additional air humidification reduces electrostatic charges on packaging materials and machinery.

Prevent dimensional changes

Controlled humidity protects the dimensional stability of paper, cardboard and paperboard.

Cooling with low energy consumption

Evaporative cooling achieves energy-efficient cooling of production halls without air conditioning.

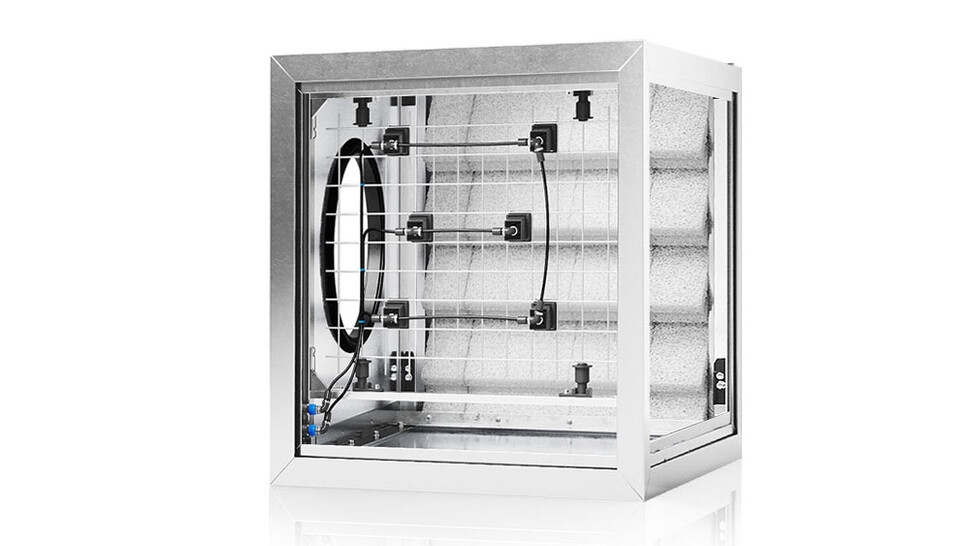

Air humidification for optimal packaging materials

Dehumidification for greater process stability

Efficient cooling – reduce energy costs

Optimal humidity

Electrostatics

Use cases

Prevent evaporative losses

Anti-static and ESD prevention

Reliable operations start with a controlled environment

Frequently asked questions

How does evaporative cooling improve the indoor climate in production halls?

What are the advantages of dehumidification in the packaging industry?

What is the optimum humidity for packaging production?

When are Condair dehumidifiers used?

Why is humidity control crucial for packaging quality and efficiency?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.