Adiabatic evaporative cooling

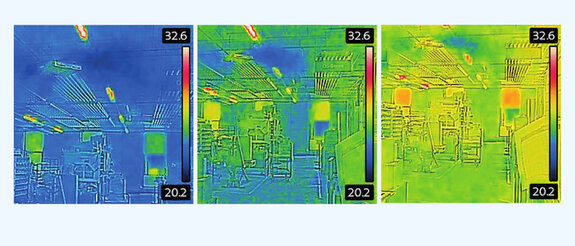

Direct room humidifiers spray microfine water droplets, thereby generating evaporative cooling.

The use of evaporative cooling with adiabatic air humidification improves the indoor climate and productivity.

Reduced heat loads with adiabatic cooling ensure optimal process parameters.

Adiabatic cooling protects health and reduces employee complaints.

Reduced costs for air conditioning and low energy consumption.

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Contact the UK office by phone, email or webform.

If you're outside the UK, find your local representative.