Benefits

Composite applications such as creating carbon fiber or similar materials require absolute humidity control to guarantee manufacturing processes that enable for consistent quality and durability.

Better quality control

Maintaining RH in range ensures consistent coatings, avoiding defects in composites.

Stable processes

Humidity control ensures quality, saves energy, prevents static and supports composite production.

Hygienic reliability

Proper humidity helps reduce material and product waste in composite manufacturing.

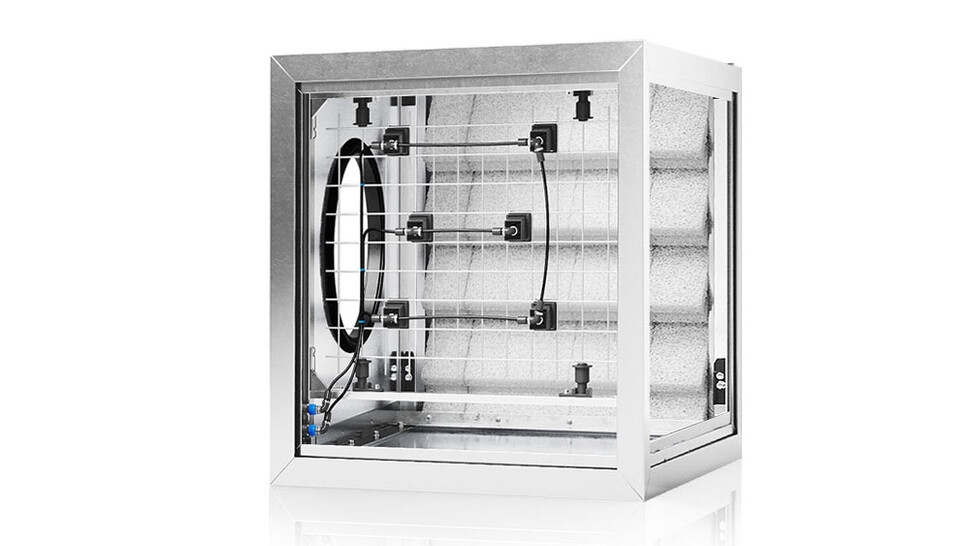

Hygienic, low-maintenance humidification systems

Precise humidity control for composite quality

Stable processes that reduce waste and downtime

Use cases

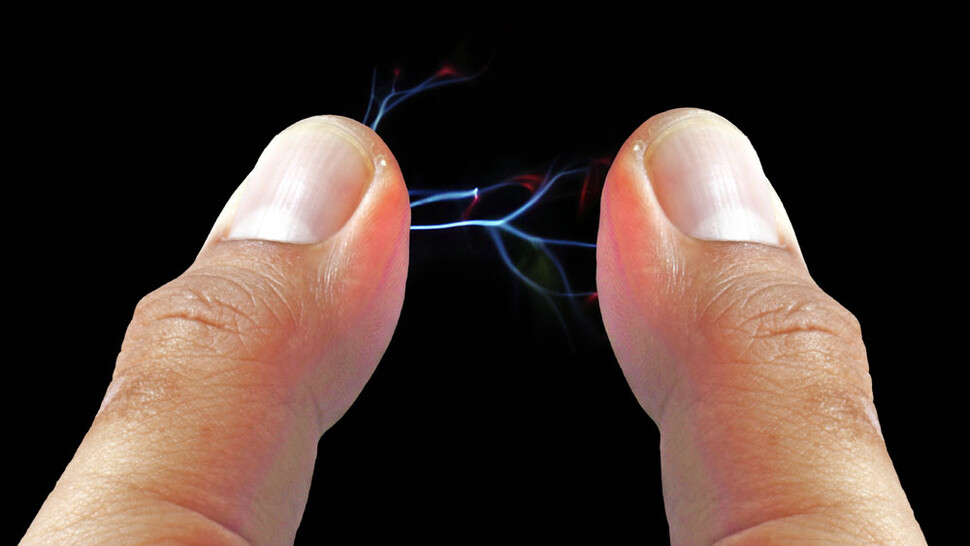

Anti-static and ESD prevention

Indoor evaporative cooling with humidification

Humidification boosts the immune system

Discover Condair in action

Frequently asked questions

What humidity level is ideal for working with composites?

What types of humidification systems are suitable for composites?

Why is humidity control important in composite manufacturing?

Can humidifiers reduce static and dust in production areas?

How can humidification systems stay hygienic and low-maintenance?

How does humidification improve product quality?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.