Benefits

Highly accurate humidity control and dry environments are essential in lithium ion battery manufacturing.

Prevent hygroscopic reactions

Extremely dry environments are necessary to prevent reactions and safety hazards.

Maintain high quality

Moisture can lead to impurities that degrade battery performance and reduce operating life.

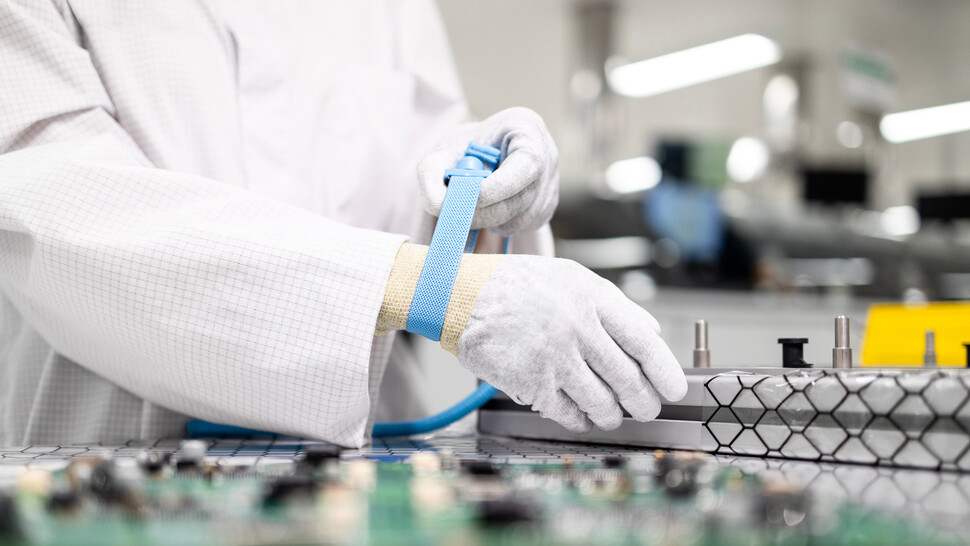

Combat ESD

Humidity reduces static build-up and ESD outside of dry rooms for many applications.

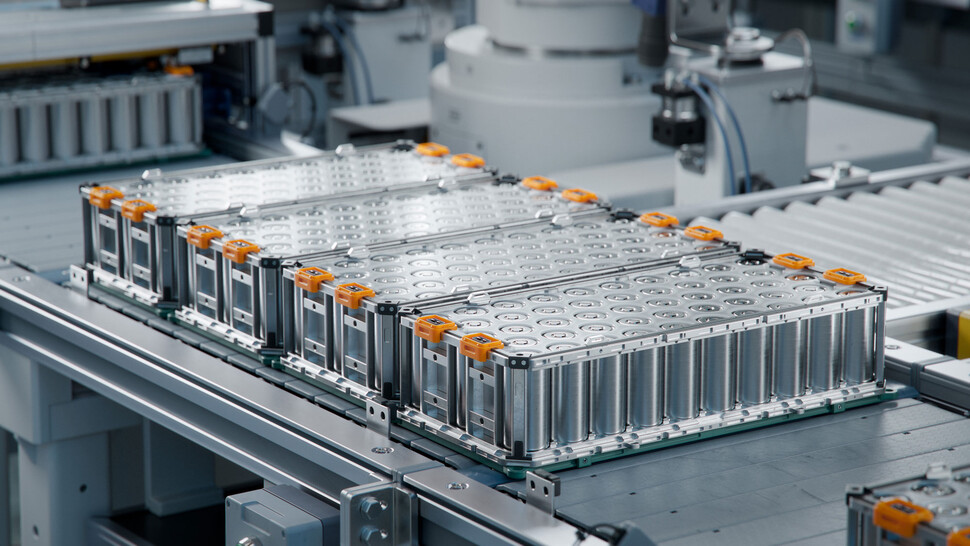

Dehumidification for lithium ion battery production

Due to the extreme requirement for moisture control, the energy required for this part of the manufacturing process is significant and therefore has a substantial impact on the profitabilty of any battery manufacturing operation.

Condair offers desiccant dehumidifier technology with energy saving features that make it ideal for battery cleanroom applications. The flexible design of Condair desiccant dehumidifiers allows the energy needed for regeneration to be taken from heat recovery systems, hot water, steam, gas or electric sources.

Condair's design team will work with a battery manufacturer to ensure that the proposed drying solution meets the required manufacturing conditions, as well as any energy consumption goals.

Humidification in battery production

Different areas of battery component manufacturing and storage can require specific levels of humidity control. Static management strategies can include maintaining an ambient humidity level of around 50%RH alongside other activities such as anti-static coating, straps and paints. ESD prevention is particularly important in processes like battery separation film production.

Condair offers a comprehensive range of humidifiers alongside its range of dehumidifiers, enabling it to be a one-stop humidity control supplier for the battery manufacturing sector.

Frequently asked questions

What are the typical humidity requirements for lithium ion battery production?

What types of dehumidifiers are used in lithium ion battery production?

How can dehumidification energy consumption be reduced?

If you want to explore your options for humidity control, Condair's expert sales engineers will visit your site, review your project and talk you through their recommendations.

Alternatively, if you would prefer a call or online meeting, our team are always happy to discuss possible solutions and offer free technical advice.

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.