Humiditfication at Akubra Hats manufacturing in Australia

Australian hat manufacturer, Akubra, has recently installed a JetSpray humidification system from Condair to humidify its forming area. The humidifier is creating the ideal air humidity to ensure a perfect finish on the felt during the manufacturing process and provide the long lasting quality Akubra is known for.

Akubra is an iconic Australian brand, a manufacturer of classic bush hats made of rabbit fur felt with wide brims that are worn widely across rural Australia and also internationally.

Ron Palin, General Manager Operations at Akubra, comments, “The key to hat making is forming the cone and this is done in the forming machine. Here, the fur is sucked onto a large revolving cone and, as it rotates, hot water is sprayed onto the fur. This interlocks the fibres in each direction. It is critical to maintain the relative humidity at 70% in the forming room to prevent any imperfections in the felt during this process, faults which will only show up later in the finishing process stages.”

Ron continues, “The Condair JetSpray is maintaining the ideal humidity of 70%RH in Akubra’s forming room. This significantly reduces imperfections in the felt, helping to deliver the highest efficiency and quality throughout the hat making process.”

Akubra engaged Condair to design and supply a low energy humidification system for installation in the large forming room area. This had to be undertaken with limited disruption to manufacturing and whilst maintaining the ideal humidity of 70%RH. Condair was chosen because of its proven track record of supplying large industrial humidification projects in Australia and worldwide.

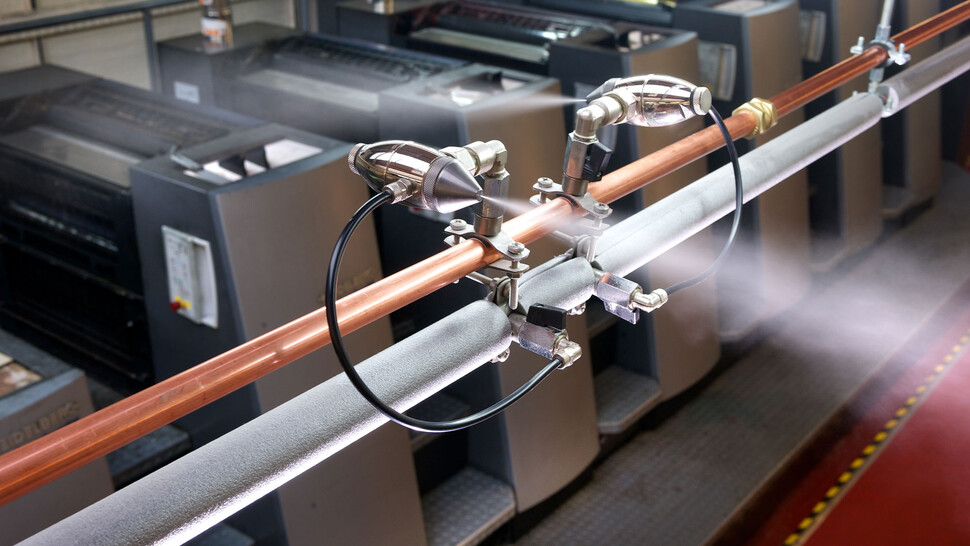

The Condair JetSpray system was selected and installed at the manufacturing plant in Kempsey, NSW. The system incorporates 18 nozzles, each capable of introducing 3.5 litres of moisture per hour into the atmosphere. A wall-mounted JetSpray control panel regulates a supply of compressed air and water, which is provided to the nozzle lines. Each nozzle perfectly combines the air and water to release extremely fine aerosols, with droplet sizes of just 7.5 microns, which rapidly evaporate into the air. The compressed air prevents any possibility of drips from the nozzles and makes the spray highly directional, thus preventing wetting on machinery, walls or the floor.

Akubra was founded back in 1874 by Benjamin Dunkerley, who came from a family of cotton weavers and who had experience working as a hatter in England. Akubra is now arguably the world’s greatest fur felt hat-making business. Each hat is handmade, with over 70 pairs of hands touching each one before it is finished and the complete process taking over one month. Combining both practicality and fashion, Akubra hats have been sported by Prince Harry, Crocodile Dundee, the Australian Olympic team and Australian military.

“The Condair JetSpray is maintaining the ideal humidity of 70% RH in Akubra’s forming room. This significantly reduces imperfections in the felt, helping to deliver the highest efficiency and quality throughout the hat making process.”

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.