Precise air humidification at Asteelflash electronics plant

Since its founding in Paris in 1999, Asteelflash has experienced impressive growth, establishing itself as one of the top 20 global EMS providers. With a total production area of approximately 160,000 m², the company now comprises 18 centres of excellence strategically located across four continents. Its comprehensive range of services extends from printed circuit board assembly and complete system solutions tailored to individual manufacturing specifications to customer-specific reverse logistics. The market segments served include general industry, as well as the energy sector, data processing, and transportation. At its largest German site in Bad Hersfeld, Asteelflash produces, among other things, integrated electronic systems and assemblies for the automotive industry.

Working with motivation and health

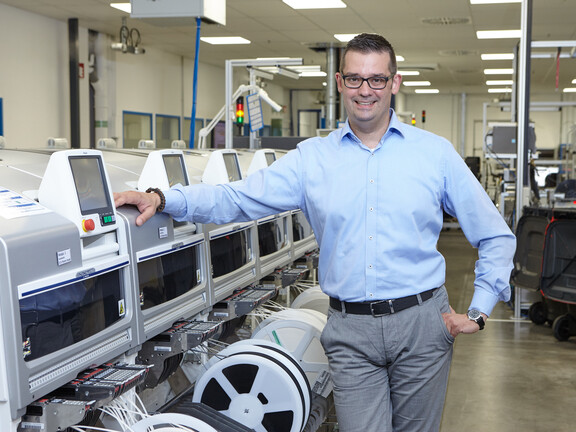

Continuously improving quality and competitiveness is one of the defined goals of the Asteelflash Group. For Felix Timmermann, General Manager of the EEMEA Region at Asteelflash, standardised processes, industry-specific quality management systems, the highest ESD safety standards, and comprehensive testing and inspection facilities are just as much a standard as a controlled indoor climate: “We want to offer our customers the best possible production conditions. Controlling temperature and humidity is crucial for ESD protection, the assembly process, the gluing and painting processes, and electrical testing.” The conviction that the quality of all services is primarily based on the expertise and skills of the employees was an additional reason for the subsequent installation of a humidification system in Bad Hersfeld: “Just as important as the technical control of the manufacturing processes is creating an optimal working environment in which our employees work with motivation and health. Sufficiently high humidity is also an important prerequisite for this,” adds Felix Timmermann.

The overall concept is impressive

Since 2016, direct room humidification has standardised humidity control in the ESD-protected production areas. Over 40 DRAABE TurboFogNeo high-pressure humidifiers guarantee an optimal relative humidity of 45% year-round. For installation, Asteelflash only required a water supply and drain, as well as a suitable power supply. The entire system is supplied from a central technical room, which houses the water treatment systems and the high-pressure pump. These are connected to the humidifiers via special high-pressure hoses and control lines. The small humidifiers, mounted on ceiling fixtures or walls, spray a microfine mist with a droplet size of less than 15 μm as needed. This mist is immediately absorbed by the air and distributed evenly throughout the room. The desired humidity level is controlled by a digital controller. In the individually defined humidification zones of the production halls, control units measure the current humidity and activate the humidifiers when the setpoint is undershot. Dominik Baumbach from Facility Management was impressed by the system's overall concept from the outset: "The individually positionable humidifiers ensure good humidity distribution in the room and, in combination with the professional water treatment system, meet all hygiene requirements."

Preventing production disruptions

As a preventative measure, controlled humidity can also have a positive effect on the pick-and-place machines: "Especially with the very small 0402 SMD components, we have less waste and fewer stray components," confirms shift supervisor Jens Bick. Optimal humidity prevents electrostatic charging of the rotating blister tapes, thus providing additional safety and preventative protection against premature failures in the field. For other processes in the production chain, such as painting, controlled humidity is an important factor in quality assurance. Electrical tests and functional tests can also be carried out with the highest accuracy, as the constant ambient humidity ensures a consistent current flow.

Delighted employees

The climate has also noticeably improved for the employees: "The air is much fresher than before; you especially notice it in your throat and nose. And in the summer, the humidification provides additional cooling," says line manager Cristian Ionita, describing the positive feedback from his colleagues. The optimal humidity prevents the mucous membranes of the respiratory tract from drying out, thus protecting against nosebleeds, burning eyes, and respiratory infections. Felix Timmermann is therefore doubly convinced of the benefits of the humidification system: "The system makes an important contribution to optimising our production processes and at the same time has a very positive impact on the well-being and health of our employees."

"We want to offer our customers the best production conditions. The control of temperature and humidity are of great importance for ESD protection, the assembly process, the bonding and painting processes and the electrical tests."

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.