Everything works smoothly

Today, Zollner's main plant in Bavaria employs 2,400 people. The success story began in 1965 with the one-man operation of company founder Manfred Zollner. The group of companies now has 17 international locations and offers complex mechatronic systems, from development to after-sales service, for renowned customers. “Technological leadership and a best-cost-country strategy along the entire value chain are a matter of course for us,” says Bernhard Kirst, Head of Marketing at Zollner. Customer requirements determine the extent of Zollner's process depth – whether individual parts, modules, devices, or complex systems. Seamless traceability and cleanroom production are also offered.

ESD protection is key

Uncontrolled electrostatic discharge (ESD) poses a major hazard in the manufacture or assembly of electronic assemblies. Triboelectric charging is the electrical charging process in which charge is generated by the contact and subsequent separation of two surfaces. For example, 100 volts is enough to erase information on a magnetic data carrier, 30 volts to damage electronic components, or less than 5 volts to damage sensitive components, whereby it is not the charging but the uncontrolled discharge process that causes damage. However, ESD protection measures are also essential during the transport and storage of components: All storage areas should be designed to be ESD-compliant, and transport packaging must also provide adequate protection for sensitive components.

Contaminants in the air

Macroparticles in the air can also have a major impact on the process result. The processing of functionally relevant components and systems requires consideration of contaminants from the environment. If contaminants are suspended in the air during production, cleanliness requirements cannot be met and this can lead to product malfunction at the customer's site. Strict compliance with air and creepage distances is essential, especially in applications such as electromobility, high-voltage, and high-current technology. The ZVEI guideline on technical cleanliness in electrical engineering serves as a basis for this.

Air humidification as a production factor

Since 2009, a direct room air humidification system has been part of Zollner's ESD protection program. At optimum relative humidity, electrical charges can be dissipated without any problems. This prevents dangerous accumulations of charges and significantly reduces particle deposits on surfaces, as the dust attraction force is much lower. Zollner manufactures in accordance with the international standard J-STD001 in the range between 30% and 70% relative humidity.

Accurate and reliable

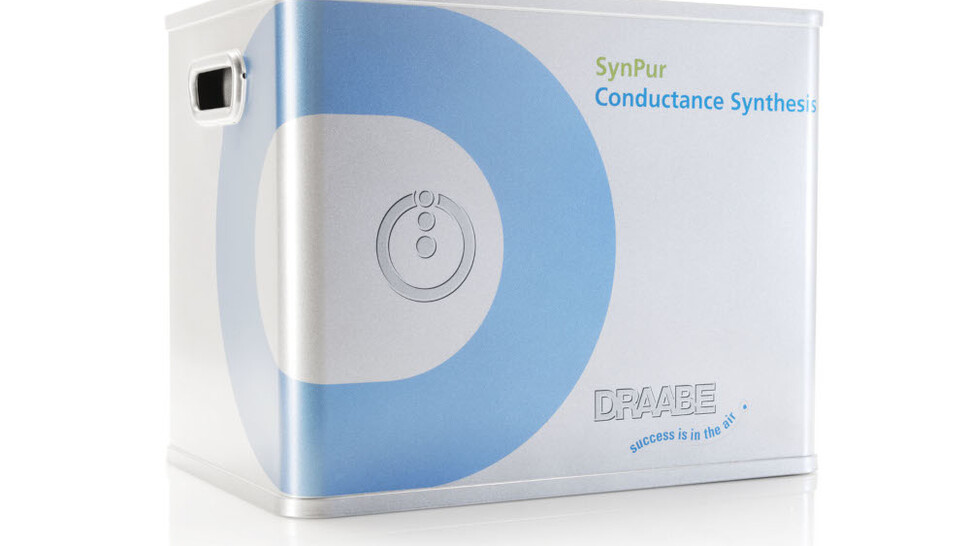

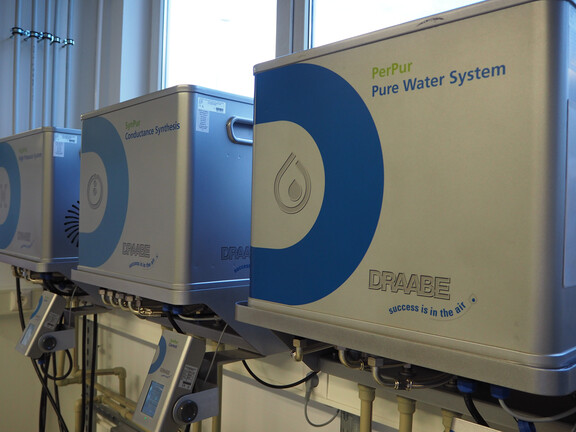

In several construction phases, parts of the 300,000 m² production area were equipped with the air humidification system – a total of 226 DRAABE TurboFog direct room humidifiers are in use. When selecting the air humidification system, Zollner placed particular importance on the individual configuration and controllability of the system. Depending on requirements, the optimum humidity levels, including their monitoring and documentation, can be set in the respective production areas to ensure controlled process conditions. “We have to be able to rely on the technology, and we are impressed by the precise measurement and control technology of the DRAABE systems,” says Jürgen Janda, Facility Management Head of Building and Construction at Zollner. The DRAABE full-service concept was also convincing. The semi-annual maintenance of the water treatment modules and all relevant parts of the air humidification system ensures that the system is hygienically flawless and operationally stable at all times. "In general, we do not outsource any responsibilities when it comes to sensitive production areas, but have our own team for maintenance and repair. However, the DRAABE full-service concept convinced us in terms of hygiene and operational safety, so that this system is also used at other production sites. We have 99% system availability and everything runs smoothly," says Janda with satisfaction.

You can't get any safer than that!

All DRAABE air humidification systems carry the DGUV test mark “Optimized Air Humidification” and guarantee a perfectly hygienic system. In addition, all DRAABE systems are certifiable according to VDI 6022 Sheet 6 for decentralized air humidification systems. This on-site inspection at the system operator's premises guarantees unrestricted hygienic operation, compliance with the necessary hygiene measures, inspection intervals, and germ limits.

"Humidity is very important for us to ensure standardized conditions throughout the production process."

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.