Direct air humidification at Bischof + Klein Konzell

Bischof + Klein (B+K) is one of Europe's leading full-service providers of flexible packaging and technical films made of plastic and plastic composites. The product range includes both traditional industrial packaging and highly refined consumer packaging, as well as innovative specialty films for technical applications. For the consumer packaging division, the Konzell site, with approximately 800 employees, has been expanded into one of Europe's largest production facilities for hygiene films. Customers include well-known brand manufacturers from sectors such as hygiene, food and beverages, pet food, and detergents.

Protection against electrostatic discharge

To protect the films from electrostatic charges during the production and processing process, an optimal relative humidity between 40 and 50 percent is necessary for quality assurance. Until 2014, B+K used recirculating air washers in the climate control duct for this purpose, recalls Martin Pritzl, who is responsible for building services engineering at the Konzell site: “However, the effort required to ensure hygiene was very high and could only be achieved with the use of biocides. Furthermore, the recirculating air system, due to the use of solvents in the production process, poses a risk to the air we breathe. Therefore, starting in 2015, we decided to gradually decommission the air washers and look for a new, maintenance-friendly, and energy-efficient humidification solution.”

Individual design

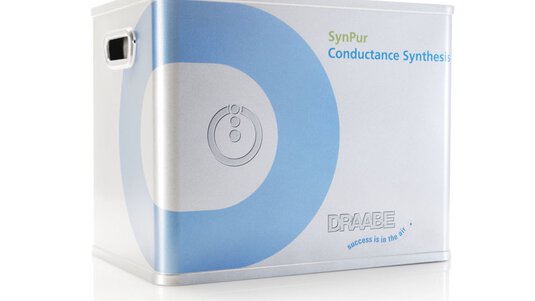

When evaluating different humidification systems, the choice fell on decentralised direct room humidification with high-pressure nozzles. "It was important to us that energy consumption be kept to a minimum and that the room climate also benefit from an additional cooling effect. Hygiene and safety of the system absolutely had to be demonstrated by documented certification according to VDI 6022 Part 6 with regular recertification by the manufacturer," explains Martin Pritzl, describing the decision-making process. Draabe TurboFogNeo and DI Flex high-pressure nozzle systems have been in operation in Konzell since 2016. The equipment types for the four production areas—extrusion, printing, lamination, and finishing—are individually designed to suit the different spatial conditions and humidity requirements. In all areas, humidity is precisely controlled by digital control units in defined humidification zones. The multi-stage water treatment system and the full-service maintenance concept guarantee consistent hygiene in the direct room humidification system: Both the system's own Draabe water treatment unit and the system's high-pressure pump are housed in portable containers that are exchanged every six months for maintenance. "This maintenance concept is very well thought out, gives us maximum security, and saves us a lot of work at the same time," says Martin Pritzl, commenting on the service.

Cooling at low cost

Based on the positive experiences with the high-pressure nozzle system, B+K in Konzell continuously expanded its humidification system for all production areas between 2017 and 2020. For the film manufacturing sector, an additional benefit of Draabe's direct room air humidification system was efficiently utilised, explains Pritzl: "The extruder machines generate a significant amount of waste heat with an electrical output of 110-120 kW, necessitating year-round cooling. Through the cold water evaporation of the humidification system, we can lower the temperature from 28 °C by an average of 2 to 3 °C with very little energy expenditure." This is made possible by adiabatic evaporative cooling.

The cooling effect occurs when the cold water evaporates from the ambient air. The change of state from liquid to gas requires energy, which is extracted from the air in the form of heat. This cooling effect results in an exceptionally economical reduction of the room temperature: 100 litres of water from the high-pressure nozzle humidification system absorb approximately 70 kW of heat while requiring only 0.6 kW of power. In addition to savings on cooling, direct room air humidification requires no additional heating compared to central humidification via the ventilation system. For Martin Pritzl, this was an additional deciding factor for the Draabe system: “Unlike cold vapour humidification via the air handling unit, the supply air to be humidified does not need to be heated. This saves considerable costs in the design of the heating coil and in operating expenses.”

Added value during the pandemic

That higher humidity not only protects against static electricity and can provide energy-efficient cooling became clear to B+K at the start of the pandemic: Informed about the connection between dry air and the spread of viruses indoors, the building services department, in coordination with B+K management, increased the relative humidity to 55 percent. Studies indicate that maintaining a minimum humidity level of 40 to 60 percent reduces the transmission risk for many respiratory infections. One reason for this is that virus-laden aerosols remain suspended in the air for a shorter time at higher humidity. Furthermore, the mucous membranes of the respiratory tract dry out less, allowing them to filter pathogens from the air more effectively. For Martin Pritzl, this is not only an additional component for health protection, but also proof of the added value and flexibility of the system: "The system was able to easily achieve the new, higher humidity levels. This is another reason why our direct room humidification system has completely convinced me as a technical system for years."

"The system was able to reach the new higher humidity levels without any problems. This is another reason why our direct room air humidification has been convincing me as a technical system for years."