Added value for employees and production

Spanning 2,300 hectares at Frankfurt Airport, Fraport AG employs approximately 21,000 people. The Airport Print Center (APC) is part of a wide range of service companies that ensure smooth flight operations. Fraport AG's in-house printing facility produces all print jobs generated at Frankfurt Airport. The product range includes not only traditional advertising printing but also the printing of all personnel and accounting documents. In addition, they offer specialized services such as lettershop services, color plotting, textile printing, and all finishing techniques. "We cover everything from a single source – from design and layout to order processing and the final product," explains team leader Michael Just, describing the APC's responsibilities. The full-service provider's clientele consists of 80% of the more than 500 companies and institutions located at Frankfurt Airport and 20% external clients. Thanks to state-of-the-art digital and offset printing technology, the APC's 13 employees can fulfill individual customer requests, even on short notice. We cover everything from a single source – from design and layout to order processing and the final product, explains team leader Michael Just, describing the APC's responsibilities.

Dry air impairs quality and speed

A major advantage for customers directly at the airport, besides the quality, is the speed with which APC completes print jobs. To be able to leverage these strengths even on short notice, the print shop must be highly flexible in responding to varying printing requirements. "Problems arose when constantly switching between media with different grammages and adjusting machine speeds accordingly," recalls Markus Leis, Deputy Head of Printing at the Airport Print Center. Dry air caused dimensional changes in the paper, such as warping and tilting. Color fluctuations and static electricity led to unwanted machine stoppages in offset printing. In digital printing, electrostatics primarily affected the finishing process. "Overall, material lead times increased, and we repeatedly lost production time," says Leis, who has worked for APC for 14 years.

In 2016, the print shop completely upgraded its Canon digital printing presses to the latest generation to operate even more efficiently. The manufacturer recommended a relative humidity of 52% for optimal printing results, with a room temperature of 21–23°C. This brought humidity back into focus. The APC saw an urgent need for action, as measurements showed a relative humidity of just under 20%.

Optimal climate thanks to high-pressure humidification

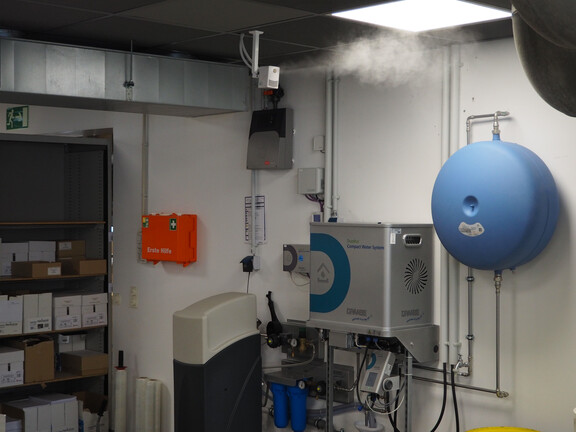

Since May 2017, the Airport Print Center has been equipped with direct room humidification from Condair Systems. Due to the low ceilings in the production areas, the Draabe NanoFog humidification system was used, which can be individually positioned according to the work areas. The complete system consists of nine high-pressure humidifiers and the compact Draabe DuoPur system, which combines a pure water system with a high-pressure pump. “The desired relative humidity of 52% is maintained year-round via digital room sensors, which only activate the humidifiers when the defined target values are undershot,” assures Matthias Tietgen, who advises the Airport Print Center on humidification from Condair Systems. For Markus Leis, the guaranteed hygiene and ease of maintenance were particularly decisive factors in choosing the humidification system: “Ultimately, the system’s certification convinced us. Furthermore, the maintenance effort is very low and practically runs itself,” Leis continues.

The integrated water treatment system guarantees that only purified and germ-free water is used. Condair Systems further ensures operational reliability and hygienic operation by replacing the water treatment system with fully serviced and cleaned units every six months. For this preventative maintenance, all Draabe systems are installed in portable containers that can be easily exchanged. The manufacturer's full-service package includes annual on-site inspection and certification of the installed system by the Association of German Engineers (VDI). Michael Just finds the concept compelling: "Condair Systems is the perfect partner. As with APC, all solutions come from a single source, and the service is truly service-oriented."

Highly efficient and highly motivated

Shortly after commissioning, the indoor climate improved significantly, and the relative humidity has remained consistently at 52% ever since. After two years of using the direct room humidification system, the conclusion is entirely positive: "We no longer have any problems with the quality and speed that are so important to us, which is also reflected in our 98.3% on-time delivery rate," says Markus Leis. In addition to the increased production efficiency, the employees also appreciate the improved air quality: "We are very satisfied with the indoor climate. The atmosphere is good, and motivation is high," says Philipp Leib, an employee at APC. This confirms recent findings from the Fraunhofer Institute, which have demonstrated a positive impact of increased humidity on well-being, motivation, and productivity in the workplace. For Michael Just, this represents a valuable double benefit: "Humidification is definitely worth the investment – for people, materials, and machinery," the team leader is convinced.

"We are very satisfied with the indoor climate. The mood is good and the motivation is high."

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.