Humidity control at Vienna’s iconic Spittelau heating plant

The most distinctive of all of Vienna’s Hundertwasser buildings is the district heating plant in Spittelau. The building houses one of three thermal waste treatment facilities operated by the company Fernwärme Wien GmbH, and was built in 1971 for the main purpose of heating the “New General Hospital,” situated some 2 km away. The giant tower with its golden orb, which can be seen from almost every high point in the city, is characteristic of the artist Friedensreich Hundertwasser.

Equally impressive is the imaginative planter above the waste delivery area. It contains several trees, which enable the experience of being in contact with nature and the changing seasons that was so important for Hundertwasser. Condair steam humidifiers ensure pleasant atmospheric humidity in the building.

The innovative control system fitted with a touch display ensures outstanding transparency of function and precise steam delivery. The units are the result of decades of experience and they define the state of the art in modern steam humidification.

Heating plant Spittelau

On the outside, it’s an impressive piece of art. But on the inside, it’s a highly efficient disposal machine. With an annual incineration capacity of 250,000 tons of waste, “Spittelau” is one of the largest waste incineration plants in Austria’s capital city. It’s also a popular exhibit for art and architecture lovers the world over, with a facade designed by Viennese artist Friedensreich Hundertwasser.

This curiosity - one of three thermal waste treatment plants operated by Fernwärme Wien GmbH and probably unique in the world - has now been renovated after three years of work. The original instructions for the project completed in June 2015 were: “The outside cannot be touched, but inside, no stone should be left unturned.”

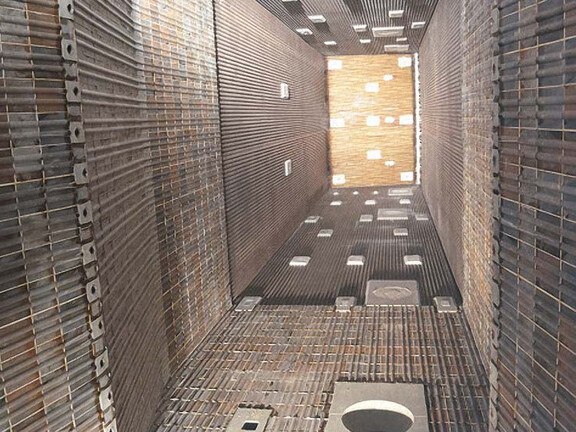

The plant was completely renovated because, after running operations for more than 40 years, major components had reached the natural end of their working life. The effort required for the renovation work was enormous, with considerable costs all in the region of EUR 130 million. First, the two 35-meter high combustion boilers, processing up to 16 tons of waste per hour and generating 54 tons of steam, had to be replaced. The pipes that transport hot steam at 400 degrees C into the turbine were also affected by the renovation, as well as the turbine itself, where the steam is eventually converted into power and used for heat extraction. In addition, there was the replacement of the catalyst and the transformer station for district heat extraction, as well as the installation of a new feed water container, an ash removal system, and a water vapour system.

Heat and power for more than 50'000 households

The importance of this generation site for the city, the second largest in the district heating grid of Wien Energie, is immense. More than 50,000 households are supplied with remote heat and power on the basis of its performance. The manpower requirement necessary during the renovation work—especially during peak periods—was equally high. Up to 400 workers were on site at times to ensure that deadlines were met. One of the two incineration boilers was able to start operation in March 2014.

Thanks to the use of modern technology, the full commissioning of the plant went hand in hand with an increase to a higher level of capacity. The plant’s power production could be increased threefold for the same output quantity of district heat. With a total capacity of 400 Megawatts and a production of 500 Gigawatt hours of heat per year on average, it’s currently one of the most modern and most efficient flue gas cleaning systems in the world.

Vienna’s Environmental Councillor Ulli Sima considers this to be a natural continuation of a sustainable environmental policy: “Modern waste treatment facilities, like the one here in Spittelau, are at the heart of our environmental and waste management plan for Vienna. District heating makes an important contribution towards the climate protection and energy efficiency of our town. Spittelau’s degree of effectiveness has been increased to 76 percent, which means that energy is utilised more efficiently.”

Condair RS

Die Dampf-Luftbefeuchter Condair RS verfügen über ein patentiertes Kalk-Management, das verhindert, dass sich Kalk an den Heizstäben dauerhaft festsetzen kann. Inkrustationen lösen sich sukzessive ab und werden aus dem Dampfzylinder in den Kalk-Auffangbehälter abgeleitet. Kalk-Management garantiert äußerst kurze Wartungszeiten und eine lange Lebensdauer.

Die innovative Steuerung per Touch-Display ermöglicht eine herausragende Funktionstransparenz sowie eine präzise Dampfabgabe. Die Geräte sind das Ergebnis jahrzehntelanger Erfahrung und definieren den Standard der modernen Dampf-Luftbefeuchtung.

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.