Humidification at Roser Printing GmbH, Hallwang, Austria

Roser Printing in Hallwang near Salzburg has developed into one of the most environmentally friendly printing companies in recent years – far beyond the borders of Austria. When Peter Buchegger took over as managing director in 2013, he had a clear objective: to continue the company's success and implement necessary changes for a successful future. "Our aim is to be the quality leader in a clearly defined customer segment, to whom we offer our services as the greenest and most sustainable printing company," Peter Buchegger succinctly summarizes his strategy.

Sustainability by conviction

The company, with its 50 employees, specializes in high-quality printing on uncoated, natural papers, including for the automotive industry, cultural institutions, and the food retail sector. For Buchegger, this high-end strategy is only possible with a competent, motivated team and a consistent focus on employees: "You can buy good machines, but not good people. A commitment to quality has to be in everyone's DNA, otherwise it won't work." The same applies to sustainability: "For us, 'green' is not just a trivial marketing buzzword, but rather a reflection of our deep conviction. We have implemented radical measures in our company with considerable effort and will continue to do so," the managing director continued. From the Austrian Ecolabel to FSC certification, the company holds nine relevant certifications and, for example, uses exclusively organic printing inks. The success of this clear positioning is evident: Contrary to the industry trend, Roser Printing has been able to grow by between 2.5 and 3 percent annually in recent years, despite the pandemic and the energy crisis.

Optimal humidity ensures quality

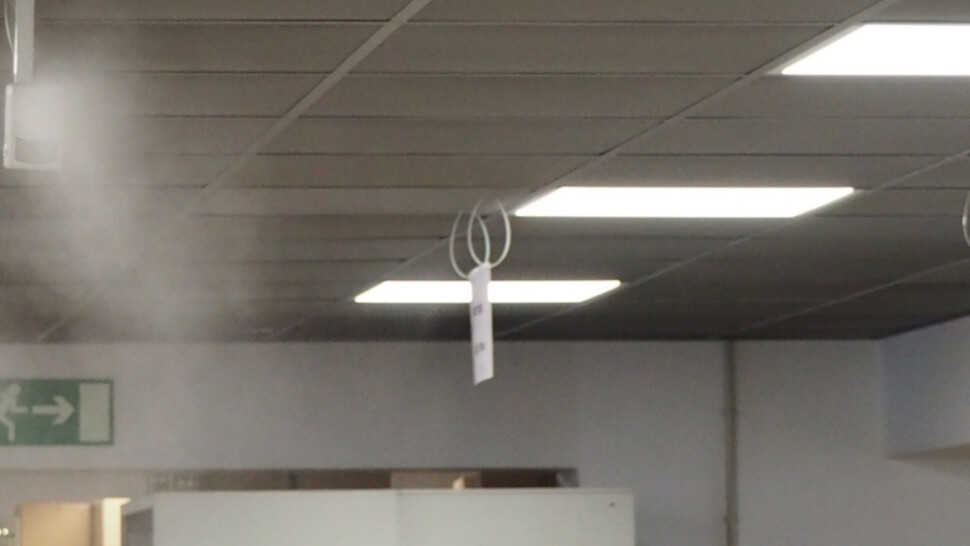

For Peter Buchegger, a key to the company's successful development was the expansion of an additional production hall, which was purchased back in 2009: "This hall was a real stroke of luck, giving us the opportunity in 2014 to expand our capacities and simultaneously invest in new technologies and processes." Today, offset printing and parts of the bookbinding department are located in the extensively renovated hall. With the move, a humidification system was also installed in the hall to ensure consistently optimal production conditions for the printing presses. "Absolute quality and adherence to deadlines are crucial criteria for our customers. Sometimes it comes down to half an hour. We can prevent quality fluctuations caused by registration errors or production interruptions due to static electricity by maintaining consistently optimal humidity," explains Buchegger. Roser Druck has been using a high-pressure humidification system from Condair Systems since 2014. Criteria for selecting the system included ultra-fine, droplet-free water mist and a comprehensive hygiene and service concept. "We didn't need a comparative quote back then. The quality offered and the expert advice convinced us from the start and haven't disappointed us since," recalls Buchegger. In 2017, the humidification system was extended to include prepress and digital printing in the older building.

In-house energy generation

For Roser Printing, profitability and sustainability, alongside quality, are the most important criteria for all investments and decisions. As for many businesses, rising energy prices have become the biggest cost driver: "Without knowing how electricity prices would develop, we made one of the best and luckiest decisions in 2020, which now allows us to produce up to 40 percent of our own electricity needs of 600,000 kWh ourselves," says Roser's Managing Director. The printing company has installed two photovoltaic systems with a combined output of 150 kW on approximately 2,000 m² of roof space. At the same time, Peter Buchegger initiated Austria's first private renewable energy community together with the energy supplier Salzburg AG: On weekends, Roser can sell surplus green electricity directly to surrounding private households and businesses. In the future, other neighboring companies will also join the energy community and install photovoltaic systems on their roofs to generate green electricity. Roser Printing can thus further increase its share of renewable and affordable energy in production: "We aim to be energy self-sufficient by 2025 and set a benchmark beyond the printing industry," Peter Buchegger explains his ambitious vision.

Green humidification

Peter Buchegger has no doubt that the humidification system, first commissioned in 2014, still meets the high demands for energy efficiency and sustainability: "I would choose this high-pressure technology and the associated service concept from Condair System again because the system perfectly aligns with our green approach." Compared to compressed air-operated nozzles or steam humidifiers, high-pressure humidification consumes up to 90 percent less energy. The water, specially treated for hygienic and safe operation, is produced in the system's own reverse osmosis unit with a yield of over 80 percent to minimize the amount of wastewater the company produces. The high-pressure pump and reverse osmosis system are housed in portable containers that are exchanged for servicing every six months and continuously reused via a closed-loop system. Regular updates and technical checks ensure that the systems maintain optimal performance even after many years of operation, without requiring new investments or additional resource consumption. Based on their positive experiences, the Roser printing company plans to expand the humidification system to other areas in the future: In addition to the entire bookbinding department, humidification could also be extended to the office spaces to create an even healthier and more invigorating indoor climate for employees. For Peter Buchegger, one goal takes precedence over all others: "If the employees are doing well, the company is doing well."

"My choice would again fall on this high-pressure technology and the associated service concept from Condair System, because the system fits perfectly with our green orientation."

Condair in Action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.