Humidification for EPDB Printing Center Ltd., Budapest, Hungary

The DRAABE TurboFog Neo system has been in use since 2019. For the company, which is part of Magyar Posta, cost reductions and quality assurance are the main advantages of controlled humidity.

Fewer printing problems

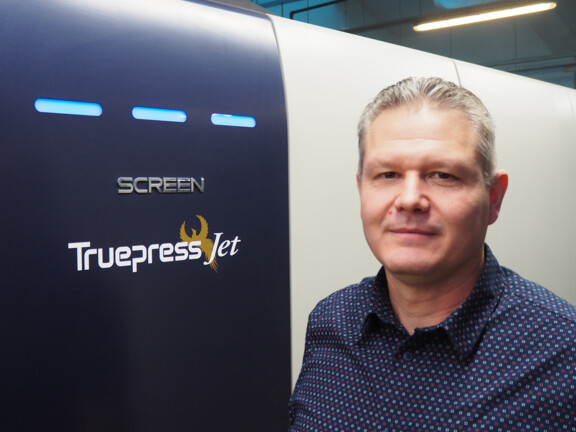

Professional database management, speed and reliability are the biggest challenges for EPDB. "To achieve this, our digital printing presses also need optimal humidity so that the fine print heads do not become clogged," says Simon István Krisztián (print shop manager), explaining the additional humidity. Until 2019, the company had used a compressed air system for this purpose. In order to reduce operating costs and get service directly from the manufacturer, the company decided to invest in a new high-pressure system.

Safe and hygienic

The DRAABE TurboFogNeo high-pressure system causes very low energy costs compared to compressed air technology. The small nozzle humidifiers can be positioned individually and adapt flexibly to the room conditions. The Maintenance: The water treatment and the high-pressure pump are installed in a small container, which is replaced by the manufacturer every six months. "This service gives us the certainty that everything always works safely and hygienically. We sometimes forget that we have air humidification at all, because everything just runs smoothly," says Simon István Krisztián happily.

"This service gives us the certainty that everything always works safely and hygienically. We sometimes forget that we have air humidification at all, because everything just runs smoothly."

Condair in Action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.