Perfect results

Gebrüder Wilke GmbH has been working with a DRAABE air humidification system at the Grevenbroich site for 15 years. Of course, air humidification should also be taken into account as a production factor in the new production hall in Hamm.

Ideal production climate

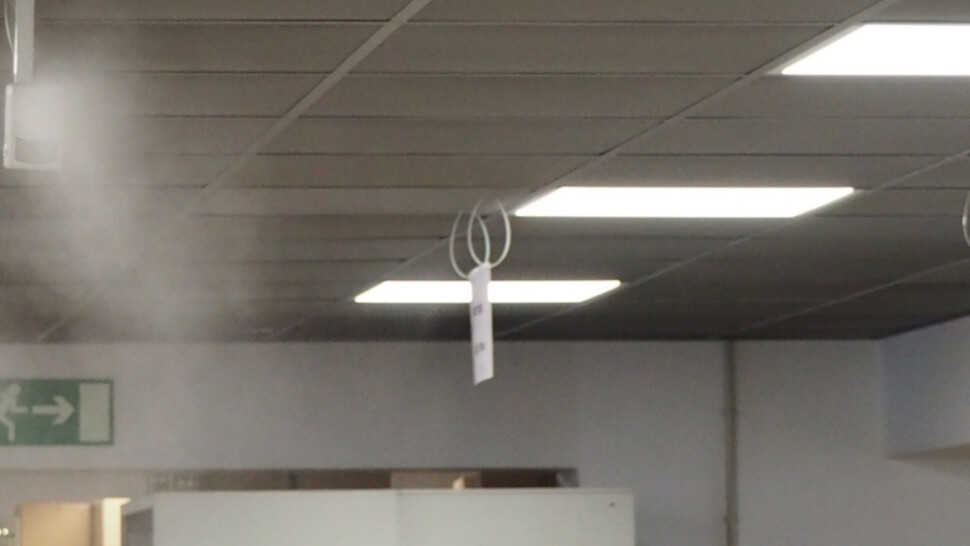

In order to ensure smooth production with the latest printing technology used and the increasing amount of paper, humidity plays a major role. Too low humidity can cause problems with electrostatics or even "plates" of the paper. Paper distortion and difficulties in printing the sheets then cause production losses and quality losses. Since the beginning of 2013, three DRAABE TurboFogNeo 8 humidifiers have been digitally controlled to nebulize a micro-fine spray mist in the new 1,500 square meter production hall. This ensures a constant humidity of 40 – 45%.

Security with VDI certification

Gebrüder Wilke GmbH was the first printing company in Germany to have the DRAABE air humidification system also certified in accordance with the new VDI 6022 Part 6. This VDI guideline describes the current state of the art for direct room air humidification and is intended to reduce the liability risk for the operator. With the six-monthly replacement of the water treatment and the high-pressure pulsation, the trouble-free and hygienically safe use of the DRAABE air humidification system is guaranteed. ""We have to don't worry about anything. For the DRAABE system, we receive good service, fast processing and you always get direct feedback. The system does what it is supposed to: it runs. And we can concentrate on our core business,"" says Andreas Wilke.

"We don't have to worry about anything. For the DRAABE system, we receive good service, fast processing and you always get direct feedback. The system does what it is supposed to: it runs. And we can concentrate on our core business."

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.