Air humidification for digital printing quality and speed

More than 6,000 visitors from Europe, the Middle East and Africa are inspired and trained here every year. "We see ourselves as a 'dream factory' that gives rise to new ideas and shows how they can be implemented in printing technology today," says Ester Chiachio, Head of the Customer Centre. Since 2013, DRAABE air humidification systems at HP have been providing the right humidity.

Steam humidification shut down

To ensure optimal print and production results, constant humidity levels are required in the HP Demo and Training Centre: "Electrostatic charges, changes in the size of the paper, and fluctuating print quality affect our training and demonstrations," explains Adam Goldthorp, HP Training Manager. "In addition," says Goldthorp, "different printing technologies and substrates (e.g. plastic, cardboard) also require different humidity values." The existing steam humidification system installed in the central ventilation system could no longer meet these requirements and was shut down in 2013.

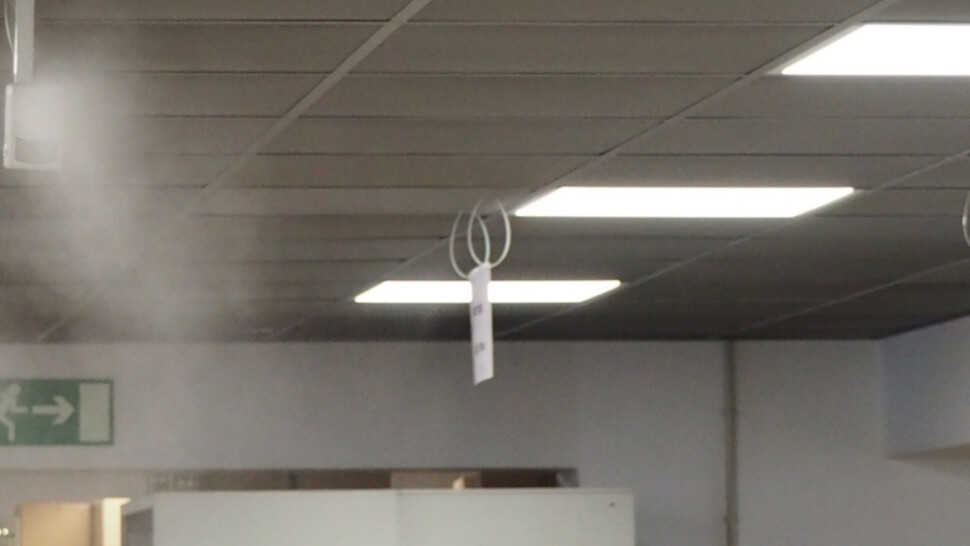

Competence and service Since then, more than 50 DRAABE TurboFogNeo high-pressure humidifiers have guaranteed controlled air humidification in the various areas. For José Baena of HP Global Real Estate, the new DRAABE technology is a major advantage: "There are now optimal values for different zones and presses. We were also able to reduce the energy consumption for humidification by over 95%." Ester Chiachio is also satisfied: "With the DRAABE system, Condair Systems is a very competent partner with comprehensive service and know-how in the printing industry and is an ideal fit for our Dream Factory" as a recommendation for our customers.

"Humidity is very important for us to ensure standardized conditions throughout the production process."

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.