Humidity for Quality Assurance - Varga Nyomda, Eger - Hungary

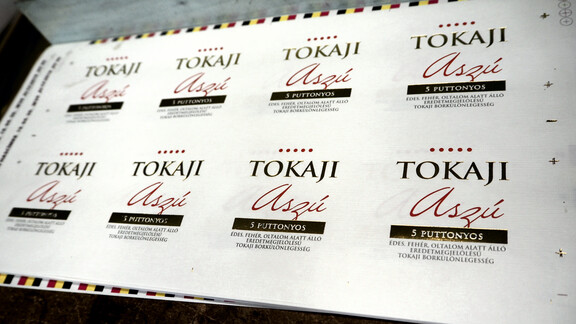

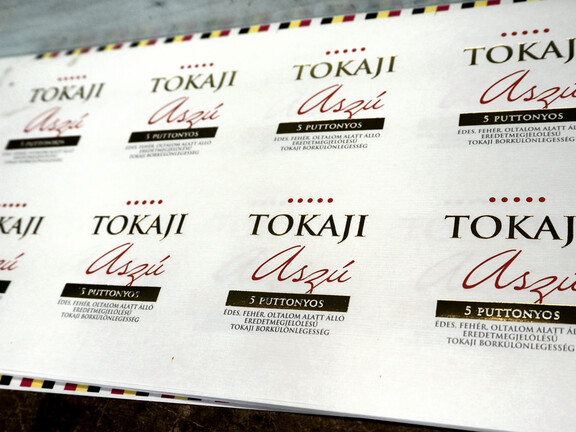

“High-quality wines need high-quality labels that visually distinguish the wine, make it unique, and evoke emotions,” Zoltán Varga is convinced. He has owned the family-run printing company for over 30 years and is now supported in management by his children, Claudia and Kristián Varga. With around 40 employees, the company, based in Eger, Hungary, primarily produces adhesive labels on sheets and rolls. Over 250 million labels are produced annually for the Hungarian wine-growing regions of Eger and Tokay, as well as for export to Austria and Slovakia.

Protection against electrostatic discharge

To produce high-end labels with great flexibility, even for small and medium print runs, Varga Nyomda invested in an additional Xeikon PX 3300 label printing press at the end of 2020. The Xeikon press offers the possibility of creating attractive effects inline with tactile white and also using metallized materials. “Our printing company places great emphasis on high quality and exceptional service that our customers don't find everywhere. State-of-the-art technology is essential for this,” explains Zoltán Varga, justifying the company's continuous investment in its machinery. The purchase of the new digital printing press also prompted the decision to install an additional humidification system. To prevent electrostatic discharge, print quality issues, and machine downtime, the Xeikon PX 3300 requires a constant relative humidity between 42 and 46 percent. For Kristián Varga, who was looking for suitable climate control solutions, the new machine wasn't the only deciding factor: “We've always had problems with excessively dry air in offset printing. Furthermore, our research revealed that optimal humidity leads to better dust suppression and improved health protection.”

Humidification with Service

Since 2021, the label specialist has been using a direct, high-pressure humidification system from Condair. The Draabe TurboFog system guarantees consistent humidity levels year-round in the printing hall and finishing areas. Kristián Varga was particularly impressed from the outset by the system's flexibility and Condair's unique maintenance and service concept: The positioning of the individual humidifiers is highly customized to the specific room layout and machine locations. Even short-notice adjustments to the humidifier positions have been necessary and, unlike with inflexible nozzle piping systems, could be implemented very easily. The consistently hygienic and safe operation of the humidification system is ensured by a multi-stage water treatment process: Before being distributed to the nozzle humidifiers, the water is specially treated by the Draabe TrePur system. In addition to filtering out impurities and demineralizing the water, it is completely disinfected and generates the required operating pressure of up to 75 bar. The system is housed in a transportable container and is automatically replaced by the manufacturer every six months for maintenance. For Kristián Varga, this maintenance concept is ideal: “The container exchange works very well. We replaced the system in just a few steps. We don't have to worry about any maintenance, cleaning, or repairs; everything is organized, making the operation of the humidification system very easy.” With the installation of the additional direct room humidification system, Varga Nyomda has implemented an additional quality assurance measure. New, high-performance technologies, motivated employees, and standardized production conditions are, according to Zoltán Varga, the three most important prerequisites for high customer satisfaction: “Controlled humidity makes a significant contribution to standardization; we no longer have pressure problems due to the room climate.”

"In offset printing, too, there were always problems with air that was too dry. In addition, we learned during our research that higher dust binding and more health protection can be achieved with optimal air fencing."

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.