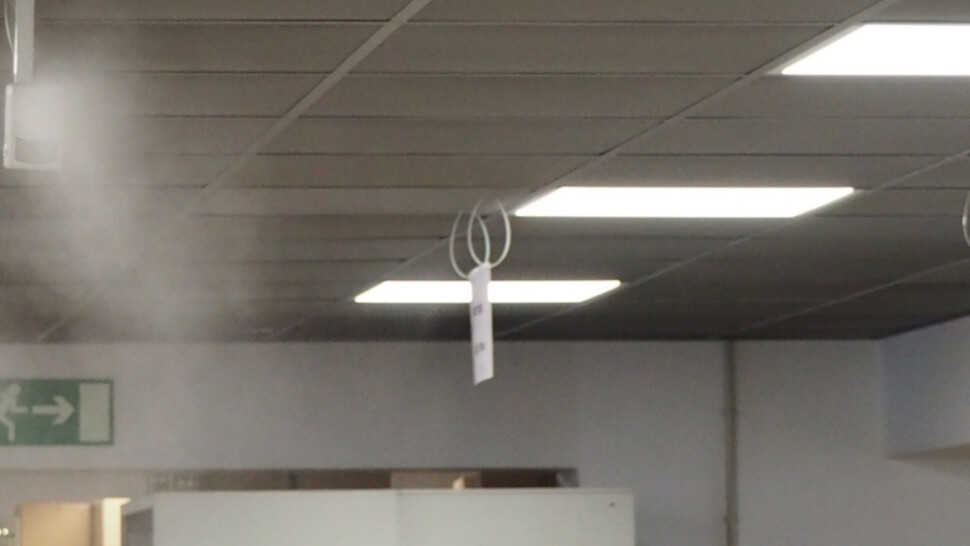

Steam humidity control at Komori Printing Centre in Utrecht

KOMORI was founded in Tokyo in 1923. Today, more than 2,000 employees worldwide contribute to the company's success. Its portfolio also includes special printing machines for producing banknotes and digital printing presses. KOMORI maintains the highest standards. “Our goal is to achieve higher output and high quality while reducing energy consumption,” says Karin van den Heuvel, Marketing Manager Europe at KOMORI.

No electrostatic charge

When paper that is too dry is processed at low humidity, static charges are generated. The paper sticks together and no longer runs smoothly through the printing press. This also applies to synthetic materials such as PVC or polypropylene. The friction process within the machine generates electrostatic charges that lead to production disruptions. A constant, optimal level of humidity ensures a fast, trouble-free production process.

No paper distortion

If the humidity in the paper storage area or printing room is too low, the material releases moisture into the ambient air. This leads to unwanted dimensional changes in the paper. The paper is then no longer flat and cannot be processed optimally. Doubling, registration differences, creasing, and curling are common problems resulting from low humidity. Only paper that is processed at optimal humidity can be printed and further processed without problems.

Consistent quality

Direct room humidification ensures optimal relative humidity throughout the year. This standardises the printing process, reduces waste, prevents machine stoppages, shortens production times, and lowers costs. The optimal equilibrium humidity for paper processing is between 50% and 60% relative humidity.

Good indoor climate

Direct room humidification creates a pleasant, fresh indoor climate in production rooms and offices. Evaporative cooling reduces the heating of interior spaces by 2–5 °C. At the same time, dust is bound and remains in the air for less time. Employees feel more comfortable and their health is protected.

The problem of dry air

KOMORI trains both its own employees and those of its customers in its showrooms in Utrecht and Paris. However, especially in winter, there were problems with electrostatic charge or paper curling due to low humidity.

Since 2012, six digitally controlled DRAABE TurboFogNeo 8 humidifiers have been ensuring constant humidity at the KOMORI Graphic Technology Centre Europe. “With the DRAABE system, we can now demonstrate our machines at full capacity all year round at an optimal humidity of 50–55% without any problems,” explains Ad Ekelschot, Showroom Manager at KOMORI. The humidity can be quickly adjusted as needed to suit the requirements of different printing substrates such as paper or film.

With safety

To ensure hygienic and trouble-free operation of the humidification system, the water is first sterilized and demineralised in a DRAABE water treatment system. KOMORI considers the ease of maintenance and the full-service concept to be particular strengths of the DRAABE system. “DRAABE fits perfectly with our corporate mission statement KANDO – beyond expectations: the functionality and performance of the air humidification system far exceed our expectations. Its use has been a complete success,” says the Showroom Manager.

"More output and high quality with decreasing energy consumption is our goal."

Condair in action

Get in touch with us

Contact us

Contact the UK office by phone, email or webform.

Find your international Condair representative

If you're outside the UK, find your local representative.